Products

Learn

Support

Company

The bending and axial code checks for single angles differ somewhat from other shape types, because single angles behave quite differently in bending and compression depending on how they are braced along their length.

.png?width=435&height=218&name=image%20(12).png)

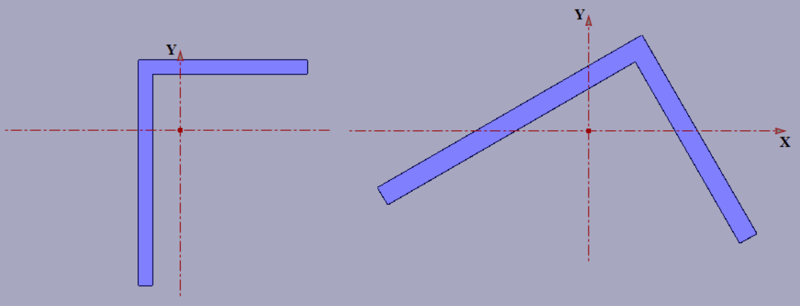

Single angles can act about their geometric axes if they are fully braced against twisting along their length. Otherwise they will bend and buckle about their principal axes.

RISA-3D automatically assumes that full bracing is not present, and that bending and buckling will occur about the principal axes. In the Detail Report of a single angle bending about its principal axes, the moments are reported as (Mz’) and (My’), which are the bending moments about the principal axes.

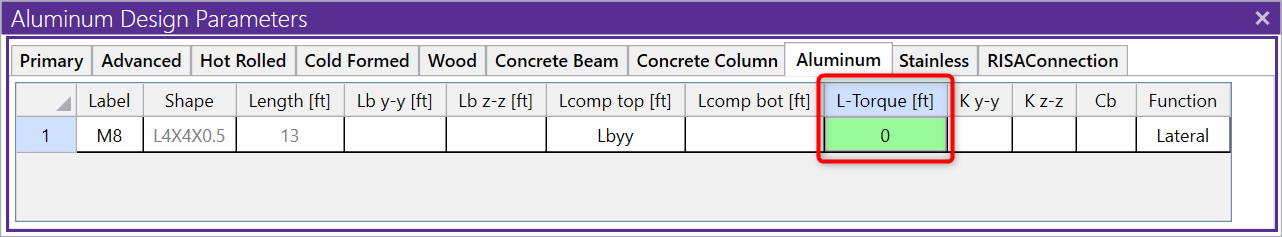

If you want the code check for a single angle to be based on bending and buckling about the geometric axes, then you must specify to the program that the angle is fully braced against twisting along its entire length. You can do this by entering an unbraced length of zero for the L-torque value.

The program uses the values of Lbyy and Lbzz to determine the compression capacity of the angle. Note that unlike steel single angles, per the aluminum code the compression capacity is always based on principal axis buckling.