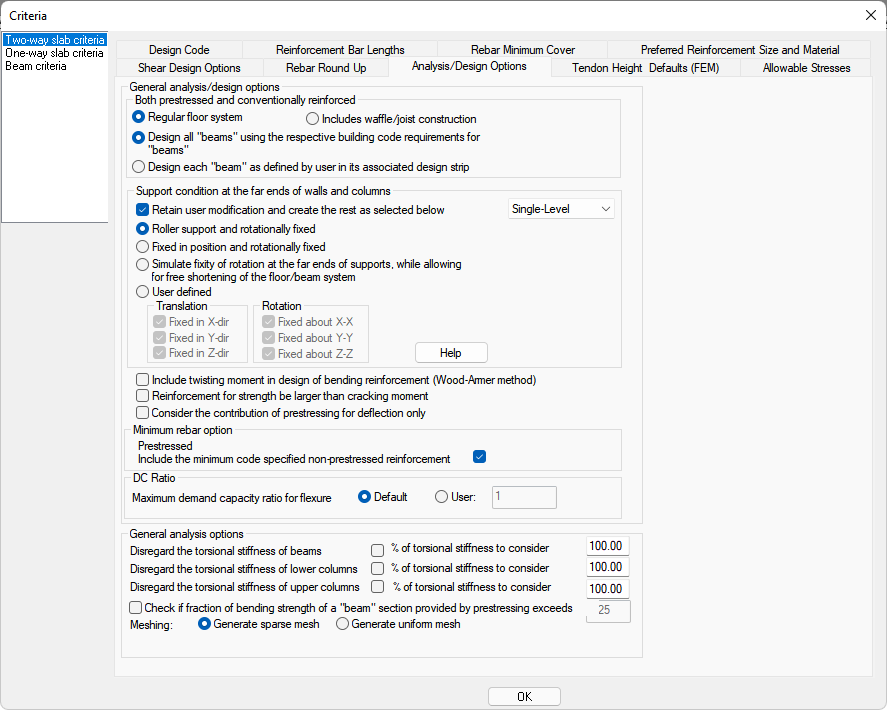

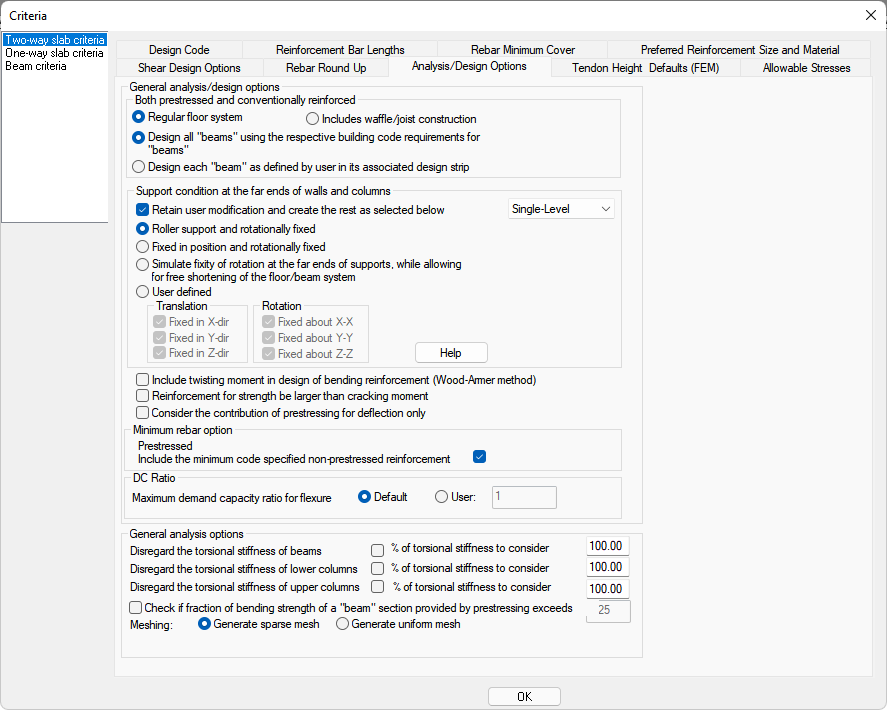

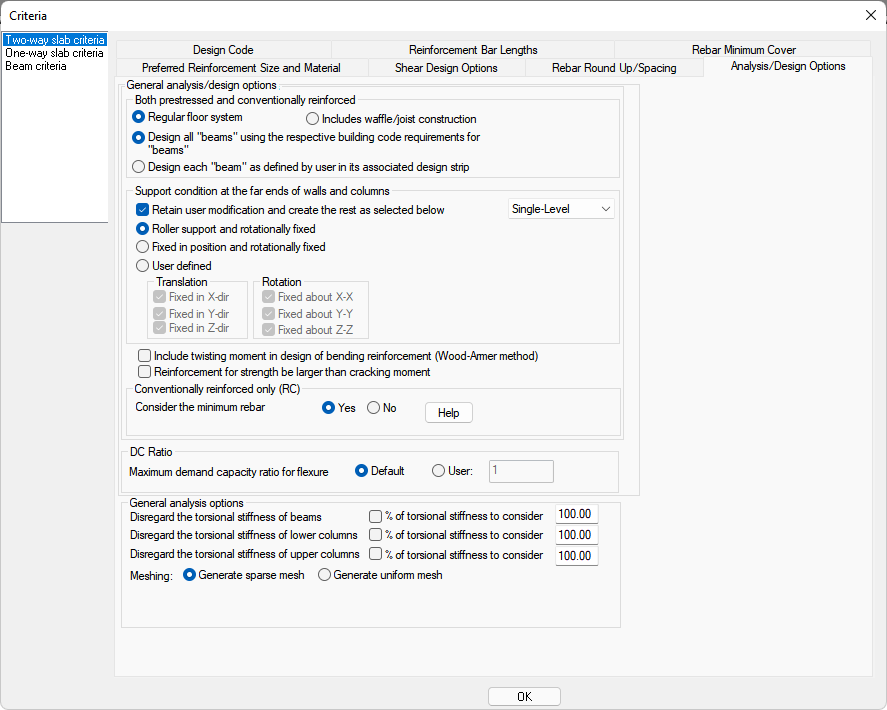

The Analysis/Design Options tab allows you to define analytical and design settings. Use this option to define default support conditions for Single and Multi-Level modes. Most often, the default values are sufficient and therefore, most often used.

Edge/FloorPro/MAT/PTRC example

Edge/FloorPro/MAT/RC only example

The following table provides descriptions for all the settings sections that appear on the Analysis/Design Options panel, based on what you are using and the building code you select.

Analysis/Design Options Settings

| Setting | Description | ||

|---|---|---|---|

|

Both prestressed and conventionally reinforced

|

These settings are used to determine how design sections consider slabs and beam components comprising section cuts, for prestressed and conventional reinforced concrete slab and beam systems. |

||

|

Regular floor system – This option is the default option and is typically used for:

When a design section intersects a slab section, which includes a beam, the program considers the beam as part of the design section geometry, under the condition that at least 1 of the support lines nodes falls in the region of the beam, and the angle between the support line and beam axis is less than 30 degrees. If this is not the case, the beam is considered for analysis, but is not considered as part of the design section. |

|||

|

Includes waffle/joist construction – This option is commonly used for waffle slabs or beam and joist systems. Regardless of where the support line node is snapped, the design section intersecting a slab and beam, or several beams, considers the beam(s) as part of the design section geometry. If multiple beams are intersected as part of one design section, the beam assumes the total sum of beam widths as the beam stem width. This option can also be applied to “regular” floor systems if you require more flexibility for support line node placement. |

|||

|

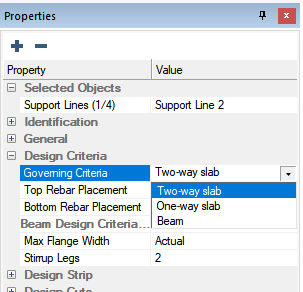

Design all “beams” using the respective building code requirements for “beams” – Each support line (used to generate design strips) is based on specific design criteria; Two-way slab, one-way slab or beam. If a beam is included as part of a continuous support line which also includes two or one-way slabs, the program automatically applies reinforcement design requirements (service and strength) for beams, based on the design code selected. Note: The allowable stress limits and preferred reinforcement sizes are dependent on the criteria setting of the support line as defined in the property grid when the support line is selected.

For example, if a support line including a beam requires 3.0 in2 of reinforcement (10#5 bottom bars) at the section located at mid-span of the beam, the required area of steel is based on beam requirements. The #5 bar size is selected due to the two-way slab criteria preferred bar size as defined on the Criteria>Preferred Rebar Size and Material tab. Stress limits would also be based off the two-way slab criteria set for the support line rather than the beam criteria. |

|||

|

Design each “beam” as defined by user in its associated design strip – You can create an independent, non-continuous support line which extends only over the beam and set the design criteria to “Beam” to achieve the reinforcement quantity AND bar size related to Beam Criteria. If this option is selected, the design section will be designed based on the support line criteria defined in the Design Criteria section of the Properties Grid.

|

|||

|

Support condition at the far ends of walls and columns

|

These settings are used to set support conditions for Single-Level and Multi-Level modes of analysis. The pull down menu for Single and Multi-Level conditions is not used to define which mode of analysis is being considered; it is used ONLY to set the support condition for each mode.

The 'Story Manager Toolbar' contains toggle buttons which change the mode from Single-Level to Multi-Level mode. This applies to the model graphically and also dictates the type of analysis performed.

|

||

|

Retain user modification and create the rest as selected below – This option ensures that any boundary conditions that you manually modify to individual components, are retained. If a component is not given specific boundary conditions, they are assigned according to the criteria listed below this setting at the onset of analysis. If this option is deselected, each time you run an analysis of the structure, the user defined support conditions are overridden to the option selected below ("Roller support and rotationally fixed" through "User-defined").

|

|||

|

Roller support and rotationally fixed – This is the program default condition for models analyzed in Single-Level mode. This condition restrains translation for the Z direction and releases the X and Y translation restraints. The X, Y and Z rotational restraints are fixed. Also known as a “fixed-roller” condition. |

|||

|

Fixed in position and rotationally fixed – This condition fixes translation and rotational fixity in the X, Y and Z axes. Also known as a “fixed-fixed” condition. |

|||

|

Simulate fixity of rotation at the far ends of supports, while allowing for free shortening of the floor/beam system – This condition is identical to the fixed roller condition (program default). Its purpose is to explicitly describe a condition for which you could simulate free shortening of a post-tensioned slab. Note: This option is unavailable in RC-only mode.

|

|||

|

User-defined – This option lets you set a customized boundary condition for translational and rotational degrees of freedom for the X, Y and Z axes. |

|||

|

Include twisting moment in design of bending reinforcement (Wood-Armer method) |

This option lets you design for twisting moments as part of the Strength design using the Wood-Armer Method. |

||

|

Reinforcement for strength be larger than cracking moment |

This option is used to satisfy the code requirement found in ACI 318 for bonded post-tensioned systems. When this option is selected, the program creates an additional load combination stored internally, called “Cracking Moment.” Reinforcement required to meet 1.2*Mcr is enveloped with other combinations. Note: You can define the modulus of rupture value used in the calculation of Mcr in the Concrete: Material Properties setting.

|

||

|

Consider the contribution of prestressing for deflection only |

This option suppresses the tendons from being considered for section capacity and stress checks. The presence of tendons is only used for solving the model of FEM results for displacements. The design of sections ignores the presence of tendons for this selection. Stresses are not reported if this option is used. The purpose of the option is for designs in which PT is used to control deflections, but slab and/or beam design is performed based on conventional RC methodology. Note: This option is unavailable in RC-only mode.

|

||

|

Minimum rebar options |

Prestressed - Include the minimum code specified non-prestressed reinforcement – This option, if unchecked, suppresses the check for minimum reinforcement. For combinations that are set to an analysis/design option type of “Service (Total)” or “Service (Sustained)" the program reports no reinforcement if this option is deselected. Note: This option is unavailable in RC-only mode.

|

||

|

Conventionally reinforced only (RC Mode Only) |

Consider the minimum rebar - The minimum rebar refers to the code required reinforcement for creep, shrinkage and temperature. If this item is not selected, the program reports the reinforcement needed for the strength limit state of the structure only.

Note: This option is only available in RC-only mode.

|

||

|

DC Ratio |

This option lets you override the limit for DC Ratio for the flexural design of sections. By default the program is coded to design strength reinforcement to a moment demand/capacity ratio of 1.0. Note that the allowable limit for the code check is hard coded at 1.0 and cannot be modified by you.

|

||

|

General analysis options

|

These settings let you adjust the torsional stiffness of members without adjusting local stiffness modifiers. These settings should be used for models run in Single-level mode only. |

||

|

Disregard the torsional stiffness of beams / % of torsional stiffness to consider – Lets you ignore the torsional stiffness (rotation about local longitudinal axis of beam frame elements) or to reduce the stiffness by entering a % of stiffness to consider in the analysis. |

|||

|

Disregard the torsional stiffness of lower columns / % of torsional stiffness to consider – Lets you ignore the torsional stiffness (rotation about local longitudinal axis, or Global Z axis, of lower column frame elements) or to reduce the stiffness by entering a % of stiffness to consider in the analysis. |

|||

|

Disregard the torsional stiffness of upper columns / % of torsional stiffness to consider – Lets you ignore the torsional stiffness (rotation about local longitudinal axis, or Global Z axis, of upper column frame elements) or to reduce the stiffness by entering a % of stiffness to consider in the analysis. |

|||

|

Check if the fraction of bending strength of a “beam” section provided by prestressing exceeds user-defined % |

This option lets you check if the portion of design section capacity, from prestressing steel, exceeds the value (entered in decimal format) specified by you. The program flags which sections exceed the threshold. From 'Results Display Settings', you can display the Positive or Negative capacities which violate the check.

If you double-click on the design section to open the Design Section input window, and review the Design Section tab for the section information, the program reports the estimated amount of additional reinforcement required to maintain the threshold value defined by you.

Note: This option is unavailable in RC-only mode.

|

||

|

Meshing

|

Lets you define how the program meshes the slab automatically. |

||

|

Sparse Mesh – Allows the meshing algorithm more flexibility in determining the slab mesh and has less restrictive internal requirements for shell size and edge length ratios. This is also known as an “organic” mesh. This is the default meshing setting. Caution: This option is no longer active. See Automatic Mesh Generation topic for more information on generating a sparse or uniform mesh.

|

|||

|

Uniform Mesh – Generates a mesh containing shells with a more uniform in size and more restrictive, on the shell edge length, ratios. This meshing selection typically results in more shells and nodes. Caution: This option is no longer active. See Automatic Mesh Generation topic for more information on generating a sparse or uniform mesh.

|