Warning Log

Click on image to enlarge it

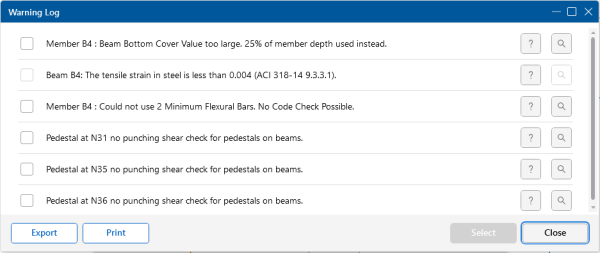

The Warning Log Spreadsheet provides you with a record of any warnings or errors that occurred during the solution of your model. The log should be reviewed for warnings or errors that would affect the design of your structure. The error log reports back the item label for which the error occurred.

You can view the warning log by clicking on the Spreadsheets menu item and then clicking on the Warning Log selection.

Pressing the ? will open the help file to give further explanation on this item.

The following table contains all possible warnings, their cause and possible solutions:

Warning Numbers

| Warning Number | Warning Log Message | Cause | Solution |

|---|---|---|---|

| WARNING 41003 | The rebar does not exist. No Capacity Calculated. | This message means that a user defined reinforcement profile has resulted in a member with zero capacity (and zero reinforcement) at the described location. | Revise the user defined reinforcement so that it is present at all locations along the member's length. |

| WARNING 41005 | Span length is less than 1 foot. No design for this span. |

RISA uses span information to perform concrete member design and rebar optimization. When a member spans less than 1 foot from support to support then the program cannot perform this design.

|

Increase the span to a length greater than 1 foot, or ignore design of this member in this short segment. |

| WARNING 41011 | The tensile strain in steel is less than 0.004 | The arrangement and amount of reinforcing steel is such that if the member fails it will fail in a brittle manner (Compression Controlled Section)). This is not allowed, per ACI 318-14, Sections 7.3.3.1, 8.3.3.1, 9.3.3.1 (ACI 318-11 Section 10.3.5) | The quantity and arrangement of rebar is such that the rebar is not yielding prior to a concrete failure. Change the dimensions of the cross section of the concrete or alter the rebar design rules such that the rebar yields first. |

| WARNING 41012 | The tensile strain in steel is less than 0.005 | The arrangement and amount of reinforcing steel is such that if the member fails it might fail in a brittle manner (Transition Section). The strength reduction factor was reduced according to ACI 318-14, Section 21.2.2 (ACI 318-11 Section 10.3.4) | This does not indicate a failure. However, the full strength of the section is not being reached. To increase the strain (and therefore increase the strength), change the dimensions of the cross section of the concrete or alter the rebar design rules such that the rebar yields first. |

| WARNING 41021 | More than 800 bars not allowed. | The concrete column solver used by RISA for our direct integration solution has an internal limit of 800 flexural bars per concrete column. This limit has been exceeded for this member. | If using a custom rebar layout, reduce the number of bars. If doing rebar optimization, use a larger minimum bar size so the program will use fewer bars. |

| WARNING 41023 | Optimize concrete beam solver error. | The concrete beam solver has encountered an error. | Contact RISA Support and send your model so that this error can be resolved. |

| WARNING 41025 | Column/Beam Cover Value too large. 25% of member depth used instead. | The program's concrete solver was not designed to accommodate very large cover values relative the member depth/width. Therefore a maximum cover value of 25% of the member's dimension in that direction was used instead of the cover value specified in the rebar design rules. | Modify the member size or the cover dimension so that the cover dimension is no more than 25% of the member dimension. |

| WARNING 41027 | Unable to Iterate Phi for a Given Rebar Strain. | For the ACI-318 2002 Concrete Code and later, the Phi value for axial/flexural loading is based on the concrete strain, and must be iterated for the Load Contour method. This iteration process has failed for this particular member and load. | Send this model to RISA so we can review the conditions under which the value of Phi could not be calculated. |

| WARNING 41031 | Slender Compression Failure (Pu > .75Pc). No Slender calculations done. | The axial compression exceeds 75% of the Euler Buckling capacity of the member. This means that the member is prone to column-type buckling, and it causes ACI 318-14/19, Eqn 6.6.4.5.2 (ACI 318-11 Eqn 10-12) to go to infinity (representing a column buckling failure) | Decrease the axial compression load on the member, or increase the cross section size, or decrease the unbraced length of the member. |

| WARNING 41034 | KL/r > 100 for this compression member. See ACI 318-05 Section 10.11.5 | ACI 318-05 and earlier concrete codes allowed the moment magnification procedure to be used in lieu of a second order analysis. RISA uses the moment magnification procedure for these codes. This was limited to members with a slenderness less than 100. ACI 318 08/11/14 do not have this limitation because of the P-Delta analysis requirement. | Increase the cross section size, or decrease the unbraced length of the member. Alternatively, use a newer version of the code where this requirement no longer exists. |

| WARNING 41042 | KL/r > 120 for this compression member. See AS 10.5.1 : 2001 | AS 3600-2001, Section 10.5.1 prohibits the slenderness of a member from exceeding 120 unless a "rigorous analysis" is performed. RISA does not perform that rigorous analysis, so therefore this limit must be enforced. | Increase the cross section size, or decrease the unbraced length of the member. |

| WARNING 41044 | H/r > 410 for this compression member. See NTC-DF2004 1.4.2.2 | NTC-DF2004, Section 1.4.2.2.b states that a non-linear second order analysis be performed if the slenderness exceeds 410. RISA does not perform that type of analysis, so therefore this limit must be enforced. | Increase the cross section size, or decrease the unbraced length of the member. |

| WARNING 41046 | Failed to satisfy minimum rebar (Temperature + Shrinkage) requirement. | The concrete rebar optimization was unable to place enough rebar to satisfy the requirements for temperature and shrinkage per ACI 318-14/19, Sections 8.6.1.1 and 24.4.3.2 (ACI 318-11 Section 7.12.2.1) | Change the cross section size or change the rebar optimization parameters in the Design Rules so that enough rebar can be placed to meet this code requirement. |

| WARNING 41048 | Program does not design Design Cuts less than 0.5 ft in the design strip. | Design cuts with a width less than 6" are not wide enough for RISA to perform a code check and design. These cuts are ignored in the Design Strip. | You may ignore this warning if you are not concerned about a code check/design at the location of that design cut. Or you may make the design strip wider at that location so that the cut is at least 6" wide. |

| WARNING 41050 | Slab is too thin to use top and bottom bars. No design done. | There is not enough space in the slab to have two layers of rebar. | Make the slab thicker so that two layers of rebar will fit. Alternatively, for foundation slabs, try using a single layer of rebar at the middle of the slab instead. You can set that in the Design Rules. |

| WARNING 41052 | Reinforcement is failing. See detail report for more information. | The program was unable to place enough rebar to meet strength requirements, or the explicit rebar provided was insufficient. | See the detail report. It is likely that the concrete dimensions need to be changed, or the rebar requirements need to be changed in the Design Rules |

| WARNING 41066 | Instabilities detected. There could be net uplift or no boundary conditions in the model. | RISAFloor or RISAFoundation solution results include very large vertical deflections, such that even though the model will solve, it appears that there is inadequate vertical restraint. If a large uplift force was applied with only compression-only springs being used for vertical restraint, the model may be have a net-uplift condition. | Examine the model to verify that all expected vertical boundary conditions are present in the model. If springs are being used, you may have to increase their stiffness value. If a net uplift condition is occurring, either increase the downward restoring force or add two way restraints. |

| WARNING 41068 | Could not find a punching shear perimeter; no punching shear check done. | The program was unable to find a punching shear failure plane for this element. Therefore no punching shear check was possible. | Review the geometry of the element and slab, specifically tracing out what the perimeter should look like. If the entire perimeter is outside of the slab then punching shear may not be a potential failure mode. |

| WARNING 41081 | Could not provide proper reinforcement distribution less than the maximum allowable. No Code Check Possible. | Concrete Design Codes have a maximum limit on the amount of flexural reinforcement to resist tension that can be placed in a given size beam. This member is unable to satisfy the required moment capacity without violating the limit on the maximum amount of tension steel that is permitted in the beam. | Increase the size of the concrete beam so that more steel can be used. Alternately, you can consider adding compression steel reinforcement, which will then let you increase the tension steel reinforcement, by using a custom rebar layout. |

| WARNING 41082 | Could not use 2 Minimum Flexural Bars. No Code Check Possible. | The program cannot design members with less than two bars. The member size, cover, spacing requirements, bar size, and stirrup size prevent two bars from being placed in this member. | Alter the cross section dimension, or modify the rebar design rules so that two bars can fit. |

| WARNING 41083 | Can't add more new rebar layout name(s). Default layout is restored. | When opening a model file that contains 1 or more custom rebar layouts that do not exist in the current library of custom rebar layouts, the program tries to add the layouts from the model file to the copy of the library in memory. If adding another layout would exceed the maximum number of layouts, no further layouts are added and members that reference a layout that could not be added will have their layout selection set to the default value. | Remove any unneeded rebar layouts from the current program library of custom rebar layouts to make room so the new layouts can be read in. Alternately, temporarily rename the custom rebar layout library file so that no custom rebar layouts are read in when the program starts up and then the model file will read in with all its rebar layouts. |

| WARNING 41088 | More than MAX_NO_MTO in MTO Report! Report was Truncated. | The Material Takeoff report is limited to a certain size, and the takeoff in your model exceeds that size. | Contact RISA to request that the maximum size of Material Takeoff reports be increased. |

| WARNING 41089 | British HR Steel: High Shear Bending Capacity Failed, Section 4.2.5.3 | The member failed. | See the code reference from the warning. |

| WARNING 41095 | Round Shapes for Beams are not supported. | No design is provided for round concrete beams | Either change the member type so that it is a column, or change the cross section to be rectangular. |

| WARNING 41096 | Required reinforcement exceeds maximum reinforcement ratios and/or reinforcement spacing restrictions. No Code Check Possible. | The reinforcement required to meet strength demand violates minimum bar spacing or maximum reinforcement ratios for the beam. | Review the Design Rules assigned to this element and make sure they are appropriate for the level of loading. Alternatively, adjust the size or thickness of the element. |

| WARNING 41099 | Rebar(s) falls outside the cross section. They are ignored in Capacity Calculation. | The user defined bar layout assigned to this member results in bars that do not fall within the cross section. | Edit the bar layout defined to this member. |

| WARNING 41100 | The rebar provided is more than Maximum Allowed by Code for a singly reinforced beam. | Acceptable steel ratios are controlled by the ACI 318 and other code provisions. The codes limit the max steel that can be used for member reinforcement. | Adjust concrete reinforcement design rules to adhere to code maximum reinforcement provisions. |

| WARNING 41102 | Factored torsional moment Tu exceeds the threshold torsion per ACI 318-14/19 22.7.4.1 | Beams and columns ignore torsion with respect to design of shear reinforcement. When using the ACI 318-02 or newer, RISA will check the member torsion value against the Threshold Torsion code provided value. (ACI 318-11 11.5.1, ACI 318-08 11.5.1, ACI 318-05 11.6.1, ACI 318-02 11.6.1, ACI 318-99 11.6.1) | The shear reinforcement will have to be designed by the engineer for torsion. |

| WARNING 41107 | Custom rebar layout does not meet min steel (As,min) per Model Settings. | The member custom reinforcement ratio does not meet the minimum steel reinforcement set in the Model Settings. | Either increase the member's custom reinforcement area or decrease the member's gross concrete area. The min steel area in the Model Settings can also be adjusted with regards to code provisions for minimum steel requirements. |

| WARNING 41108 | Custom rebar layout does not meet min steel (As,min) per ACI 318 requirements. | The member custom reinforcement ratio does not meet the minimum steel reinforcement per code provisions. | Either increase the member's custom reinforcement area or decrease the member's gross concrete area. |

| WARNING 41110 | Unable to provide min steel (As,min) per ACI -318 requirements. | The member's reinforcement design does not meet the code requirements for minimum steel reinforcement ratio. | Increase the member's reinforcement design rule to meet code provisions for minimum steel reinforcement ratio. |

| WARNING 41120 | The shear tie spacing does not meet the code Minimum Requirement. | Member shear tie spacing is less than the minimum spacing allowed by the applicable code provisions.. | Adjust the member shear tie spacing to meet code minimum requirements. |

| WARNING 41121 | No investigation! Circular layout is applied to a rectangular section or vice versa. No design done. | Either a custom circular reinforcement layout has been applied to a rectangular member or a custom rectangular reinforcement layout has been applied to a circular member. | Define a custom rebar layout applicable to the member shape type. |

| WARNING 41123 | Span qualifies as a 'Deep Section'. No Design for this Span. | Span qualifies as 'deep beam' per ACI 318-14/19 Section 9.9.1.1(a) (ACI 318-11 Section 10.7) where the member clear span is equal to or less than four times the total member depth (h). | RISA does not design for deep beams. The engineer is responsible for member design. |

| WARNING 41125 | Shear bars are not provided along entire column length. | Generally, concrete columns will have shear bars provided along the entire length of the column because of lateral confinement requirements. This member has its shear bars assigned using a custom rebar layout (it's not being optimized) and there is a region where no shear bars were specified. | Look at the shear rebar layout being used for this column and make sure there are no regions without shear bars. If the concrete design code being used permits columns to have regions without shear reinforcement, this warning can be ignored. |

| WARNING 41126 | Data missing in XML file Record Ignored. | Data is missing in the wood database XML file referred to in the model. | Edit or enter useable data in the XML wood database at the given row and column. |

| WARNING 41129 | Invalid design rule offset is detected in a section. Changed to the first design rule in the list. | The program has detected corrupt information for the specified element's design rule. The design rule was changed to the first listed design rule. | Recheck entries for the specified element's design rule for any inconsistencies. |

| WARNING 41138 | No Design of Slabs with Thickness < XX. | The slab thickness is less than the indicated thickness. No design is done. | Increase the slab thickness or the slab design needs to be done with hand calculations. |

| WARNING 41139 | No Design of Design Cuts with Width < XX | The design strip width is less than the indicated width. No design is done. | Increase the design strip width to receive reinforcement design. |

| WARNING 41140 | Top/bot cover value too large. 40% of thickness used instead. | The program's concrete solver was not designed to accommodate very large cover values relative the thickness. Therefore a maximum cover value of 40% of the element's thickness was used instead of the cover value specified in the rebar design rules. | Modify the element thickness or the cover dimension so that the cover dimension is no more than 40% of the thickness. |

| WARNING 41157 | Footing bottom cover value too large. 25% of thickness used instead. | The program's concrete solver was not designed to accommodate very large cover values relative the thickness. Therefore a maximum cover value of 25% of the footing's thickness was used instead of the cover value specified in the rebar design rules. | Modify the footing thickness or the cover dimension so that the cover dimension is no more than 25% of the footing thickness. |

| WARNING 41158 | The soil pressure exceeds the allowable bearing at node XX | The soil bearing pressure at the given node exceeds the user defined soil bearing pressure located in the Model Settings or the Soil Regions spreadsheet. | One option is to increase the footing or slab size to distribute the applied loads over a larger area. |

| WARNING 41164 | Duplicated joint for plates not allowed. | Two or more of a plates four corner joints have been set to the same joint location. The plates cannot have duplicate joints. | Send this model to RISA so we can review the conditions under which the duplicate plate joints are being created during the automatic meshing. |

| WARNING 41165 | Joints for a plate are not coplanar. See Slabs-Automatic Meshing. | The area selected for plate automatic meshing are not within the same plane. | Correct the boundary points that define the automatic mesh area to be co-planar. |

|

WARNING 41166

|

MadCap:conditions="Primary.Online_only">Poission's ratio of a plate must be >= 0. and <= .5. |

The ratio of the plate's lateral strain to axial strain does not fall within the allowable range.

|

Adjust the properties and/or the applied loads on the plate to meet the allowable Poisson's ratio range.

|

| WARNING 41167 | Pedestal at XX no punching shear check for pedestals on beams. | A pedestal location is located along a beam span. No punching shear check was done for the pedestal. | The punching shear check must be taken into account by the engineer, otherwise, specify a pedestal location not along a beam span. |

| WARNING 41168 | Cover value too large in punching shear check. 40% of thickness used instead. | The cover specified for the element used for punching shear checks is too large. 40% of the element's thickness was used instead. | Decrease the element's cover dimensions in order to get a punching shear check for the specified value. |

| WARNING 41169 | Pile cap definition: The pile layout was not recognized and has been defaulted to the two pile layout. | The pile layout previously assigned to this pile cap definition was not a standard layout recognized by RISAFoundation. It has been reset to a two pile layout. | Go to the Pile Cap Definitions Spreadsheet and set the pile layout to one of the standard layouts available. |

| WARNING 41170 | Max Limit Exceeded! - Records not read. | When opening and reading a model file, one more Program Limits were exceeded in the data sections shown in the Warning Log. | This situation can occur if a model created in the 64 bit version of a program is opened in the 32 bit version of the same program. In certain rare cases, we may have reduced the allowable number of some data elements in later program versions. Alternately, the file may have gotten corrupted. You can send the file to RISA Technologies so we can see why the program limits are being exceeded, and in some cases we can fix the model file. |

| WARNING 41171 | The lowest flex Fy was used for all slabs. Check the model to correct them. | RISAFoundation model files prior to version 3.1 can contain Design Rules with different Flexural Steel Fy values for different design strips that are on the same Slab. Starting in version 3.1, the Flexural Steel Fy value became a property of the Slabs themselves so the lowest Flexural Steel Fy value for all the design strips on a slab was used for the Fy value for that slab. | Examine the model to verify that Fy stress being used for the Flexural Steel in the is appropriate. If necessary, you may need to change the model and create additional slabs to have different Fy values. |

| WARNING 41172 | The lowest shear Fy was used for all slabs. Check the model to correct them. | RISAFoundation model files prior to version 3.1 can contain Design Rules with different Shear Steel Fy values for different design strips that are on the same Slab. Starting in version 3.1, the Shear Fy value became a property of the Slabs themselves so the lowest Shear Steel Fy value for all the design strips on a slab was used for the Fy value for that slab. | Examine the model to verify that Fy stress being used for the Shear Steel is appropriate. If necessary, you may need to change the model and create additional slabs to have different Fy values. |

| WARNING 41199 | Pile at XX no punching shear check for piles under beams. | Placing a pile under a beam element will provide support for that element. However, piles will give a punching shear check only when supporting a slab. | You may need to perform a hand calculation of punching shear in this case. Alternatively you could make the beam a slab element. |

| WARNING 41200 | Piles at XX and XX have overlapping punching shear perimeters. Group punching shear check not done. | Two piles have overlapping shear perimeters. The program does not consider the combined perimeter in punching shear checks. See the Punching Shear - Design topic for an illustration of this. | You would need to perform hand calculations to check group punching. |

| WARNING 41201 | Pile cap cover value too large. 25% of cap thickness used instead. | The program's concrete solver was not designed to accommodate very large cover values relative the thickness. Therefore a maximum cover value of 25% of the pile cap's thickness was used instead of the cover value specified in the rebar design rules. | Modify the pile cap thickness or the cover dimension so that the cover dimension is no more than 25% of the thickness. |

| WARNING 41203 | Pile cap thickness violates the code minimum depth requirement | Clause 15.8.3 of the CSA A23.3-2004 Canadian code and clause 14.4.1 of SBC 304-2007 both require a minimum depth of pile cap. | Increase the pile cap size to meet this requirement or perform a hand calculation of this pile cap. |

| WARNING 41206 | An overlap detected between two entities. | Two entities (footings, pile caps, wall footings, slabs, etc) can not occupy the same space. | Delete one of the entities, space them further apart, or reduce the size. |

| WARNING 41219 | Mesher Error | Something has gone wrong in the RISA mesher. This particular warning contains troubleshooting code for the RISA developers. | Contact RISA Support. Send your model, and the exact warning you get. |

| WARNING 41241 | Distance between beam control points (Z,X) and (Z,X) is too close. Try moving beam. See Slabs-Automatic Meshing. | The distance between the specified elements' end points or boundary edges are too close for the generation of the slab mesh necessary for analysis. | Increase the distance between end points or boundary edges by moving or redrawing the element(s). |

| WARNING 41267 | No rebar layout found for member XX, Optimize assigned. | The rebar layout defined for the given member was not found. The "Optimize" option will be used instead. | If a custom rebar layout is preferred over optimization, reassign a custom layout to the given member from the available custom layout options currently in the model. |

| WARNING 41288 | Column has a span less than 5 analysis sections. Cannot Perform Concrete Design. | The concrete column is too short for an accurate design. Less than 5 cuts could be made in its span, so Flexural theory would not be applicable. |

In order to perform concrete rebar design, the program needs to have

a good representation for what sort of moment and shear diagrams exists

in the member. When there are less than 5 internal sections in a beam

or span, the program will warn you that it did not have enough information

to perform an adequate concrete design. Increasing the number of

internal sections on the Model Settings Dialog may correct this problem.

Since, the program wants to perform shear design at a distance "d" from the face of support, it may not be possible to get rebar design for members with a large depth and a relatively short span. Keep in mind that this will only affect rebar design. Deflection and force results are unaffected. |

| WARNING 41289 | Wall footing design requires at least one service combination and at least one design combination. No wall footing design! | In order to get retaining wall footing design, at least one service load combination and one strength load combination are required. | Designate in the Load Combinations spreadsheet at least one service load combination and one strength load combination. |

| WARNING 41290 | Currently selected concrete design code is not supported for wall footing design. | The code currently selected in the Model Settings does not support retaining wall design. | The retaining wall will need to be designed by the engineer or select a code that does support retaining wall design. |

| WARNING 41291 | Wall footing cover value too large. 25% of footing thickness used instead. | The program's concrete solver was not designed to accommodate very large cover values relative the thickness. Therefore a maximum cover value of 25% of the footing's thickness was used instead of the cover value specified in the rebar design rules. | Modify the footing thickness or the cover dimension so that the cover dimension is no more than 25% of the thickness. |

| WARNING 41498 | The solution file was created with an older version of RISA. Some information may not be present. | The solution file saved with the model was saved with an old format that may be missing some data which the new version would provide. | Re-solve the model in the new version. |

| WARNING 41500 | Internal Results Corrupted | Solution results may be corrupted. Please contact RISA. | Contact RISA. |

| WARNING 41505 | Shear Fy for Material: Exceeds the Limits of ACI 318-14/19 Section 20.2.2.4 | The shear Fy for the material used exceeds the limits given in ACI 318-14/19 Section 20.2.2.4 (ACI 318-11 Section 11.4.2). | Decrease the shear Fy value for the applicable material to meet these requirements. |

| WARNING 41507 | The slab fails to meet the minimum cover requirements per ACI 318-14 Section 20.6. Adjust the cover in the Design Rule. | The slab design rules do not meet the minimum requirements per ACI 318-14/19 Section 20.6 (ACI 318-11 Section 7.7). | Adjust the cover value in the Slab Design Rules spreadsheet to meet the minimum cover requirements. |

| WARNING 41509 | No strength combination solved. Design cuts won't be designed! | No strength load combinations were solved for in the model, therefore, no design was done for the slab design strips. | Designate at least one strength load combination in the Load Combinations spreadsheet in order to get design strip results. |

| WARNING 41510 | XX is not designed, design of connected components, if any, may be affected. | The design of the specified element was not done. Connected component design may have been affected. | Check the detail report of the specified member to understand why design of the member was not done and correct the issue. |

| WARNING 41519 | An intersection detected between XX and ZZ. | Contact RISA for more information. | Contact RISA for more information. |

| WARNING 41521 | Distance between the points is too close. See Slabs - Automatic Meshing. | The distance between the given points is too close for the slab plate mesh to be generated. | Increase the distance between the given points or decrease the slab mesh area in the Model Settings. |

| WARNING 41522 | Distance between the point XX and slab boundary is too close. See Slabs - Automatic Meshing. | The distance between the given point and the slab edge boundary is too close for the slab plate mesh to be generated. | Increase the distance between the given point and the slab edge boundary or decrease the slab mesh area in the Model Settings. |

| WARNING 41526 | Section set: Shape Name changed from XX to ZZ. | The shape name denoted in the given Section Set has been changed in the database. | Accept changes or change the shape name in the Section Properties dialog box. |

| WARNING 41527 | Rebar falls outside of the lintel in the Wall Panel. This lintel is not designed. | Contact RISA for more information. | Contact RISA for more information. |

| WARNING 41549 | An overlap detected between openings or design regions | Two openings or design regions may not occupy the same space. | Delete one of the two elements so that there is no more overlap. |

| WARNING 41577 | The pile cap at point XX is failing for either a strength or reinforcement check. See the detail report for more information. | There are many ways that a pile cap can fail and one was found in the referenced pile cap. | View the detail report for the pile cap, looking for code checks exceeding 1.0 or red warning messages (regarding minimum reinforcement requirements for example) and manually adjust the pile cap. |

| WARNING 41580 | Pedestal at XX has a punching shear perimeter that intersects an opening; no punching shear check done. | The program currently can not handle punching shear checks near openings in the slab. | Edge or corner punching shear checks need to be done manually for this case. |

| WARNING 41582 | Retaining wall XX is failing for either strength, serviceability or reinforcement checks. See the detail report for more information. | There are many ways that a wall footing can fail and one was found in the referenced wall footing. | View the detail report for the wall footing, looking for code checks exceeding 1.0 or red warning messages (regarding minimum reinforcement requirements for example) and manually adjust the wall footing. |

| WARNING 41584 | Unsupported load at node XX | There are loads in the model that do not have a foundation element under them. | Either delete the unnecessary loads or place foundation elements under them to provide support. |

| WARNING 41585 | Retaining wall RW1 is in net uplift for one or more load combinations. Design not done. | If there are uplift loads applied to a retaining wall that cause a net upward force then the wall is unstable and this message is given. | Look graphically at the load combinations run in the model to see if there are large uplift loads applied in certain combinations. If so these combinations are likely causing this problem. |

| WARNING 41603 | The user defined Shear Modulus(G) for material XX is substantially higher than E/2(1+v) so it is being ignored; objects using this material will be treated as isotropic. | A check is done on materials in the Materials spreadsheet to determine whether the input E and G values are matching. If G is much greater than mechanics of materials would suggest, the program will ignore the G and use the E/2(1+v) value. | No action is required. |

| WARNING 41604 | The user defined Shear Modulus(G) for material XX is below the isotropic value of E/2(1+v); plates/walls/diaphragms using this material will be treated as orthotropic. | A check is done on materials in the Materials spreadsheet to determine whether the input E and G values are matching. If G is much smaller than the E/2(1+v) value this warning is generated and the input G is used. | If this G was input on purpose then no action is required. If not then you may wish to update or delete your G value in the Material spreadsheet. The program will auto-calculate G if left blank. |

| WARNING 41633 | The solution file is not from the same version as the program currently trying to read it. It was deleted. | The solution file saved with the model was saved with a different version of RISA. | Re-solve the model in the new version. |

| WARNING 41634 | Insufficient memory to read the Solution Results file. It was deleted. | There is not enough memory to read the solution file. | Try solving the model using a Sparse Solver to reduce the amount of memory needed for the solution file. |

| WARNING 41635 | There is a problem with the Solution Results file. It was deleted. | There solution results file was unable to be read. | Contact RISA. |

| WARNING 41636 | An error occurred while reading Solution Results file. It was deleted. | The solution results file was unable to be read. | Contact RISA. |

| WARNING 41639 | Single leg shear reinforcement is not supported and is present in the model file. All instances using this were changed to the minimum number of allowed legs for shear reinforcement, which is two. | This model was previously created using single leg shear reinforcement which is not supported. | The concrete reinforcement design rule was changed to have two legs for shear reinforcement. This is the minimum that is supported by the program. |

| WARNING 41644 | BS EN 1992-1-1:2004+A1:2014 is not supported for Spread footing design. Select a supported code for design. | The selected code is not supported for spread footing design. | For spread footing design results, please select a supported code. |

| WARNING 41645 | BS EN 1992-1-1:2004+A1:2014 is not supported for Pile design. Select a supported code for design. | The selected code is not supported for pile design. | For pile design results, please select a supported code. |

| WARNING 41646 | BS EN 1992-1-1:2004+A1:2014 is not supported for Wall footing design. Select a supported code for design. | The selected code is not supported for wall footing design. | For wall footing design results, please select a supported code. |

| WARNING 41647 | BS EN 1992-1-1:2004+A1:2014 is not supported for Pile Cap design. Select a supported code for design. | The selected code is not supported for pile cap design. | For pile cap design results, please select a supported code. |

| WARNING 41651 | DSX-XX: Top cover value is larger than the slab thickness. Top cover is reduced to ensure the rebar is within slab thickness. | The specified top cover is larger than the actual thickness of the slab. As such, the top cover was reduced to fit the reinforcement. | The top cover has been reduced to place the reinforcement within the slab. Consider changing the top cover for these slab design rules. |

| WARNING 41652 | The %s is not tension controlled in accordance with Table %s. | The arrangement and amount of reinforcing steel is such that if the member fails it will fail in a brittle manner (Compression Controlled Section). This is not allowed, per ACI 318-19, Sections 7.3.3.1, 8.3.3.1, 9.3.3.1. | The quantity and arrangement of rebar is such that the rebar is not yielding prior to a concrete failure. Change the dimensions of the cross section of the concrete or alter the rebar design rules such that the rebar yields first. |

| WARNING 41653 | The program does not consider the minimum slab requirements due to punching shear. Check Detail Report of column/pedestal for additional information. | ACI 318-19 requires a minimum slab reinforcement at punching shear critical section if vuv>φ2λφ√f’c per Section 8.6.1.2. RISA currently does not consider this in slab reinforcement design. | Users need to consider separately the required additional slab reinforcement at punching shear critical section to account for this code requirement, RISA provides the calculations of As,min per Equation (8.6.1.2) in the Detail Report. Please refer to column/pedestal Punching Shear Results for additional information. |

| WARNING 41686 | Unable to expand environment strings on user specified temp directory path. | Problem with the user specified temp directory path. | Check/revise your temp directory path. |

| WARNING 41687 | Unable to expand environment strings on user specified temp directory path because result is too long. | Problem with the user specified temp directory path. | Check/revise your temp directory path. Try setting it to a local location. |

| WARNING 41688 | User specified temp directory path cannot be used due to permission errors. | Problem with the user specified temp directory path. | Check/revise your temp directory path. |

| WARNING 41689 | User specified temp directory path cannot be used because it does not exist. | Problem with the user specified temp directory path. | Check/revise your temp directory path. |

| WARNING 41690 | User specified temp directory path cannot be used because it is not on a local disk. | Problem with the user specified temp directory path. | Check/revise your temp directory path. Make sure it is pointing to a local location. |

| WARNING 41691 | User specified temp directory path cannot be used because due to an unexpected error. | Problem with the user specified temp directory path. | Check/revise your temp directory path. |

| WARNING 41692 | Error reading user specified temp directory path. | Problem with the user specified temp directory path. | Check/revise your temp directory path. |

| WARNING 41693 | The default CFS panel group XML files are missing, and no other alternatives were found. Using dummy values. | The CFS panel group XML files are missing. | Re-install the program to obtain the correct CFS panel group XML files. |

| WARNING 41704 | Bottom rebar spacing for design rule 'XX' exceeds the limit of 18 in. deemed by ACI code. | The ACI code does not allow max rebar spacing for mat slabs greater than 18 inches. | The Max Spacing parameter in the design rule was adjusted to satisfy ACI criteria. |

| WARNING 41705 | Top rebar spacing for design rule 'XX' exceeds the limit of 18 in. deemed by ACI code. | The ACI code does not allow max rebar spacing for mat slabs greater than 18 inches. | The Max Spacing parameter in the design rule was adjusted to satisfy ACI criteria. |

| WARNING 41706 | The mesh size is wrong, Default mesh size is considered. | Mesh size may have been set to 0 or to a very small value. | The program will automatically use the default mesh size. User can define a different mesh size. |

| WARNING 41711 | Member XX: The explicit rebar space provided exceeds the Maximum Allowed by Code for a singly reinforced beam. | The reinforcement spacing exceeds the maximum spacing allowed by the selected design code. | In the Design Rule, modify the number of bars such that the provided spacing meets the code requirements. |

| WARNING 41717 | No XX XML files found. Internal Default properties used. | No XML file was found. | The default XML will be utilized. |

| WARNING 41718 | XX XML file was ignored. The filename is empty after trimming. File: XX; | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41719 | XX XML file was ignored. The filename is too long. XX chars allowed. File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41721 | XX XML file ignored. Failed to load. XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41722 | XX XML file ignored. Invalid format - missing Workbook tag. File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41723 | XX XML file ignored. Invalid format - missing Worksheet tag. File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41724 | XX XML file ignored. Invalid format - missing Table tag. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41725 | XX XML file ignored. No rows found. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41726 | XX XML file ignored. Invalid format - %s index out of order. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41728 | XX XML file ignored. Row 1 missing or empty. File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41729 | Error occurred while loading XX XML files. Error: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41730 | No loadable XX XML files found. Internal Default properties used. | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41731 | XX XML file ignored. No loadable rows found. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41732 | Worksheet in XX XML file ignored. No loadable rows found. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41733 | XX XML file ignored. Row 2 missing or empty. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41734 | Wallpanel XX: Two layers of reinforcement (each face) should be used for walls thicker than 210mm (14.1.8.3). | More than a single layer of reinforcement is required when the wall is thicker than 210mm. | Specify two layers of reinforcement (each face) in the Wall Design Rules. |

| WARNING 41736 | XX XML file ignored. Invalid Format - XX index XX is not a valid number. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41737 | XX XML file ignored. Invalid Format - XX index XX is out of range. Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41740 | XX XML file ignored. Invalid format - Worksheet tag missing XX: Name attribute. File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41741 | Worksheet in XX XML file ignored. Name is empty after trimming. Worksheet XX File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41742 | XX XML file ignored. First worksheet name is empty after trimming. File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41743 | XX XML file ignored. First worksheet name is too long. File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41744 | Worksheet in XX XML file ignored. Name is too long. Worksheet XX File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41745 | Worksheet in XX XML file ignored. Name conflicts with a previously loaded worksheet. Worksheet: XX File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41747 | Record ignored in XX XML file. Matching record in first worksheet not found. Row: XX Col: 1 Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41748 | XX XML file ignored. Expected %s. Row: XX Col: XX Worksheet: XX File XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41749 | XX XML file ignored. Based on earlier column headers expected XX. Row: XX Col: XX Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41750 | XX XML file ignored. Expected XX. Row: XX Col: XX Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41751 | XX XML file ignored. Units specification must be empty. Row: XX Col: XX Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41752 | XX XML file ignored. Expected "UNITS" or an empty cell. Row: XX Col: XX Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41753 | Record ignored in XX file. XX Row: XX Col: XX Worksheet: XX File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41754 | XX XML file ignored. After trimming the name conflicts with a previously loaded file. File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41755 | XX XML file ignored. Too many files. Only XX files are supported. File: XX | Invalid XML file will be ignored. | The default XML will be utilized. |

| WARNING 41769 | Shear Modulus entered does not match Poisson's Ratio. | Not a problem for nonisotropic materials. | This message warns you that the shear modulus value that has been directly entered does not match the value that would be calculated from the entered Young's modulus and Poisson's ratio. This isn't necessarily a problem; |

| WARNING 41804 | Masonry compressive strength for %s exceeds specified compressive strength requirements per TMS 402-22: Table 4.3.1 | The compressive strength defined for the masonry material exceeds the maximum compressive strength permitted for concrete masonry per TMS 402-22 Table 4.3.1. | Reduce the masonry compressive strength for the indicated material definition within the permissible range for the selected masonry design code. If designing with clay masonry, higher compressive strengths may be permitted by the design code and this warning can be ignored. |