Wafflemat's Post-Tensioned Slab Waffleboxes

Southlake, TX

Project Quick Facts

Building Client

Various Contractors

Structural Engineer

Wafflemat

General Contractor

Various Contractors

Software Used

ADAPT-Builder

Structural Components

Post-Tensioned Concrete Slab

Year Completed

Since 1995

Project Background

Wafflemat, a Texas-based manufacturer of permanent void form systems made from recycled HDPE, provides an innovative foundation solution designed to reduce concrete waste, simplify construction, and improve slab-on-grade performance across diverse soil conditions. As the company expanded into new regions, transparency in design and analysis became a top priority. To support this mission, Wafflemat developed an in-house engineering program focused on producing clear, code-aligned foundation designs that contractors and design professionals could trust. This shift allowed the company to move away from opaque, third-party methods and toward a standardized workflow that demonstrates exactly how their foundation system performs in various geotechnical environments.

sq ft foundations

slab depth

wafflebox spacing

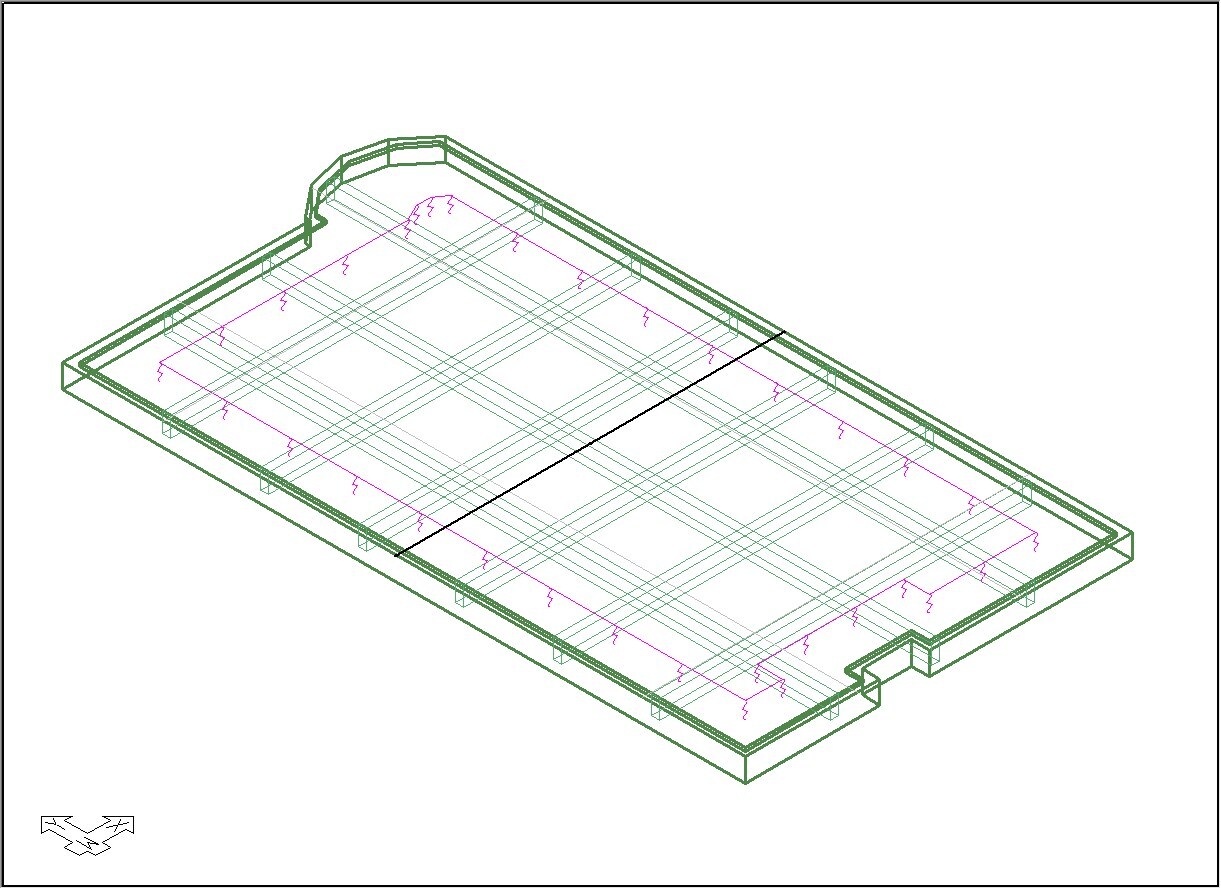

About the Structure

Wafflemat foundations are used widely in residential, commercial, and shallow-foundation applications. Because each region can present unique geotechnical challenges — from non-expansive soils in Hawaii to highly expansive clays in North Texas — Wafflemat’s system must be analyzed with precision to ensure reliable performance under both gravity and soil-induced loads. The unconventional geometry of the void form system requires more advanced modeling than traditional empirical slab-on-grade methods can provide. Accurate representation of soil springs, panel behavior, and edge displacement is essential for validating the system and presenting defensible calculations to engineers, contractors, and owners.

"The transparency and reliability of ADAPT have been crucial in refining our design methods and ensuring that our solutions are effective across various regions."

Anna Olveda, PE

How Were RISA Products Utilized?

Wafflemat selected ADAPT-Builder as the foundation of its finite element design workflow because of its ability to accurately model complex slab-on-grade systems. With ADAPT-Builder, the team can model soil-structure interaction—including soil springs and edge movements—tailored to regional geotechnical conditions, while also simulating unconventional slab geometries that fall outside the limits of empirical design methods. The software enables clear comparisons between traditional and optimized foundations, illustrating material savings, improved performance, and construction efficiencies through transparent FEA-based results. It also supports a consistent, repeatable workflow that can be applied across varying soils, climates, and project types nationwide. Close collaboration with ADAPT’s technical team further refined Wafflemat’s modeling assumptions and ensured alignment with accepted engineering standards. As a result, Wafflemat is now able to deliver defensible calculations to contractors and design consultants, strengthening trust, restoring confidence on delayed or overbudget projects, and contributing to significant business growth—including an influx of shallow foundation work from contractors who value the transparency of the ADAPT-driven process.

Images 1-3: Wafflemat

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.