Waffle Building

Culver City, CA

Project Quick Facts

Building Client

Frederick and Laurie Samitaur Smith

Structural Engineer

NAST Enterprises Corporation

General Contractor

Samitaur Constructs

Software Used

RISA-3D

Structural Components

Steel Framing, Steel Plates

Year Completed

2017

Project Background

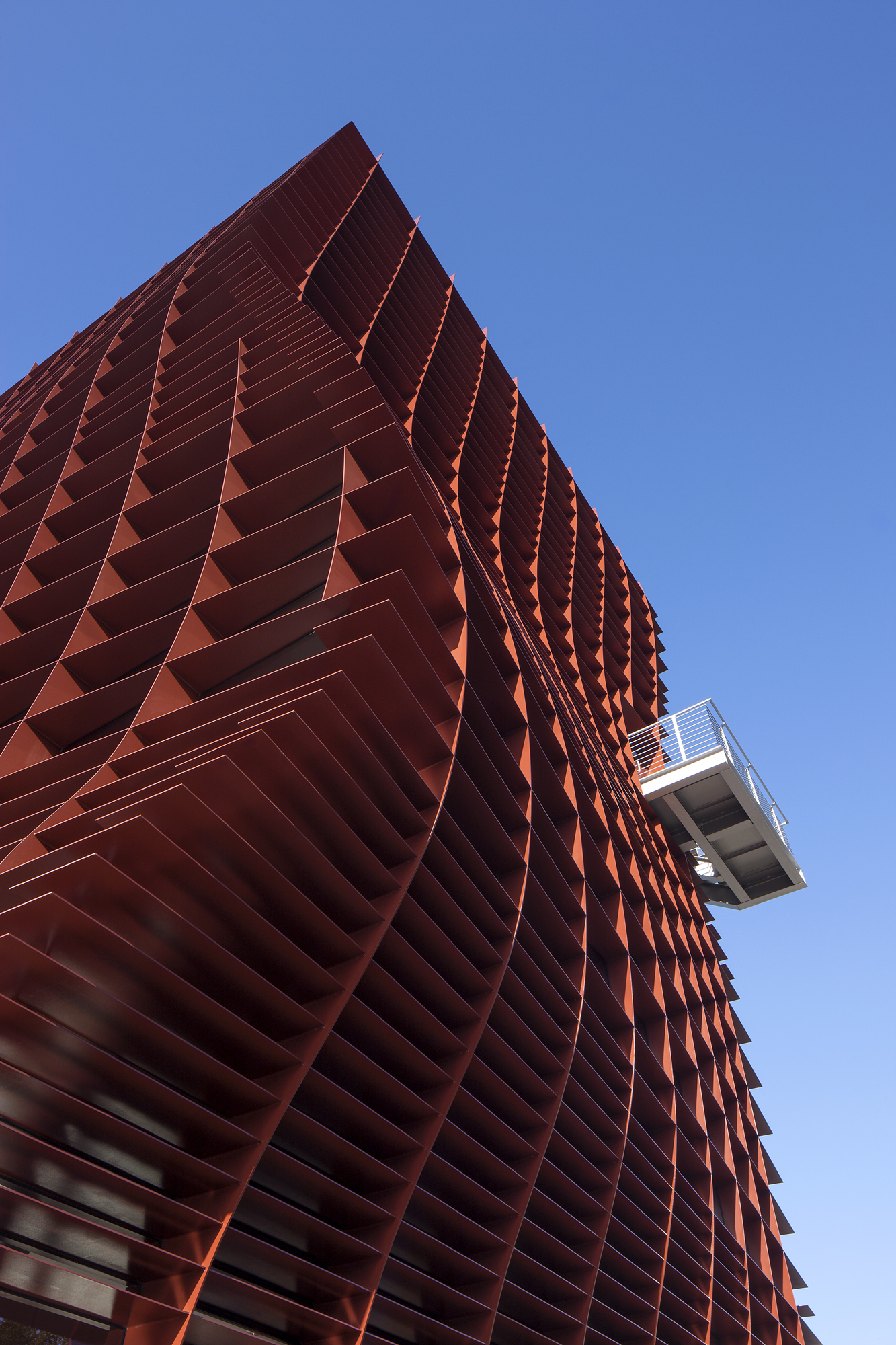

The Waffle Building, located in Culver City, CA is an undulating four-story building that grew out of a collaborative vision between architect Eric Owen Moss and chef Jordan Kahn, whose restaurant, Vespertine currently occupies the building. The structure, which only occupies a space that is 33 ft x 33 ft, twists along its height and is enveloped in horizontal and vertical steel fins which make up the “waffle” grid and support the glass enclosure. The program of the space includes a ground floor lobby, a mezzanine level that serves as the main dining floor and an open-air roof deck that is connected via elevator and internal stairs. The building is the 2019 Innovative Design in Engineering and Architecture with Structural Steel (IDEAS2) Award winner for projects less than $15 million.

sq ft footprint

stories

height

About the Structure

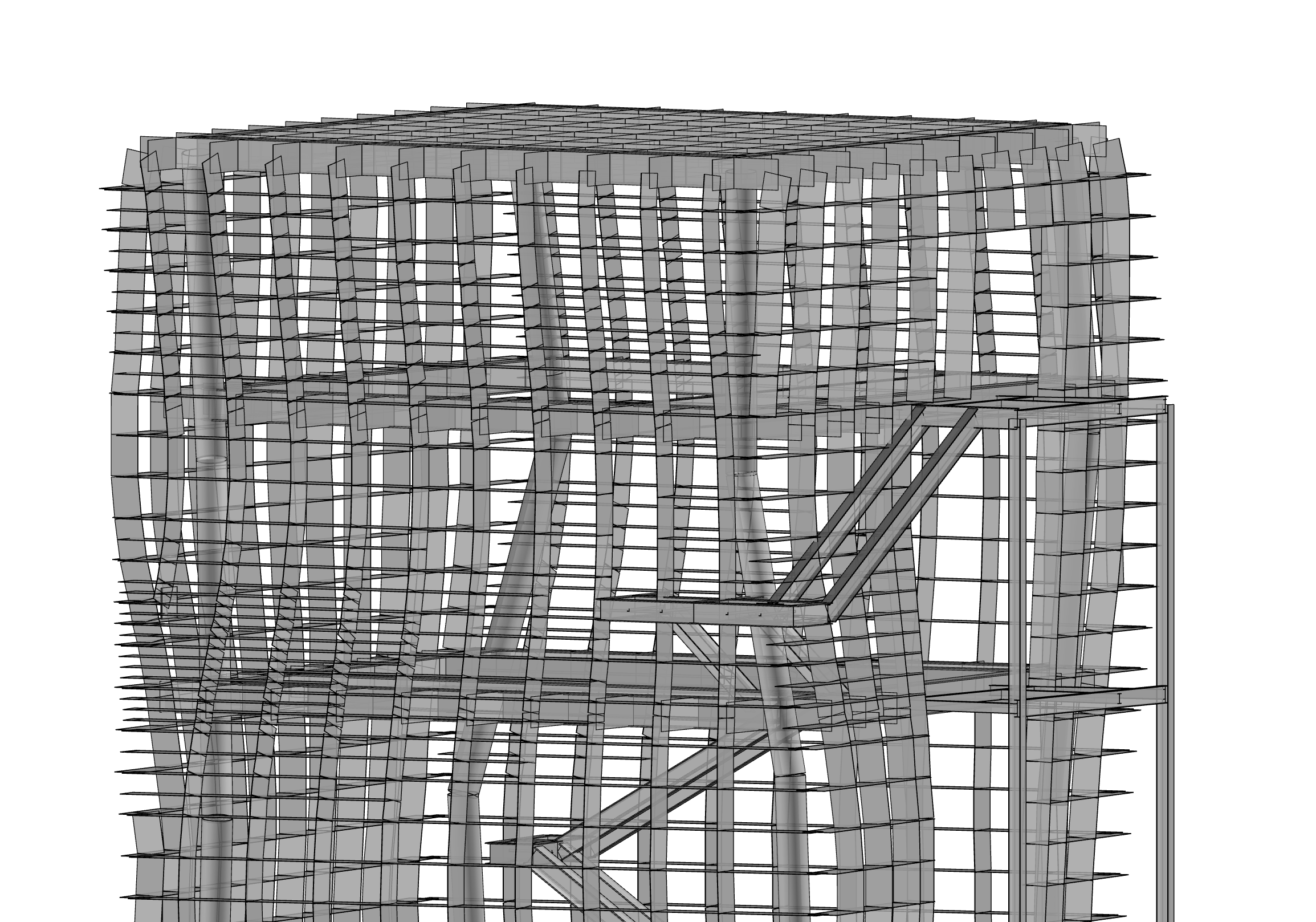

The internal supporting structural system closely follows the exterior shape with four, 18-inch diameter steel pipe columns situated at the corners with steel beams and steel joists supporting each level. The complex geometry of this relatively small structure made collaboration between the architect and structural engineer essential. One of the most unique challenges was evaluating the performance of the exterior ¼” steel plates. RISA-3D along with its submeshing and loading features were used to accurately evaluate the stresses in the plates to ensure their performance. Furthermore, because these plates were integral to the architectural aesthetic of the building, special consideration was given by the contractor and steel erector during installation to ensure that the plates weren’t subjected to load that would cause them to deform.

"I have found RISA-3D to be both the most versatile and powerful tool that we use"

Hooman Nastarin, PE

How Were RISA Products Utilized?

The single biggest design challenge on the project was understanding and managing the various deflection “modes” of the structure during construction. For instance, early in construction (before the exterior steel “fin” plates were installed) the structure acted like a flexible piece of metal with large eccentric deflections at the corner. Fortunately, this behavior was anticipated due to the engineers commitment to creating an accurate representation of the structure in RISA-3D. Overall, these models played a key role in predicting and validating the deflections that the contractor was experiencing on site during construction and installation allowing for the project to be built as intended.

Images 1, 2 & 4: Tom Bonner Photography

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.