Binghamton University Smart Energy Building

Binghamton, NY

Project Quick Facts

Building Client

Binghamton University

Structural Engineer

Ryan Biggs | Clark Davis

General Contractor

Fahs Construction Group

Software Used

RISA-3D

Structural Components

Steel Frame, Concrete Foundations

Year Completed

2017

Project Background

The new 105,000 sq-ft Smart Energy Building at Binghamton University is part of a series of laboratory research facilities being built on campus. The $45 million building consists of several separate programmatic spaces including two laboratory “pods”, the atrium that connects them and a rotunda structure that links the building with the Center for Excellence (COE). Overall, the main function includes physics and chemistry research lab spaces with a focus on the development of future energy technologies.

sq ft

lab pods

rotunda diameter

About the Structure

The main structural system consists of steel framing on a concrete basement and concrete spread foundations. Moment frames are used in each direction within the laboratory “pods” to resist lateral forces. Additionally, the first floor of each “pod” was designed for floor vibrations due to human activity according to AISC Design Guide #11. Overall, the buildings use of curved, round HSS members serves as one of its primary visual features and achieves the architects vision of creating visual interest from both the interior and exterior of the structure while also allowing the engineer freedom to develop a structural concept that would be feasible.

"RISA-3D’s functionality and ease of use make it an indispensable part of our design process."

Chris Latreille, PE

How Were RISA Products Utilized?

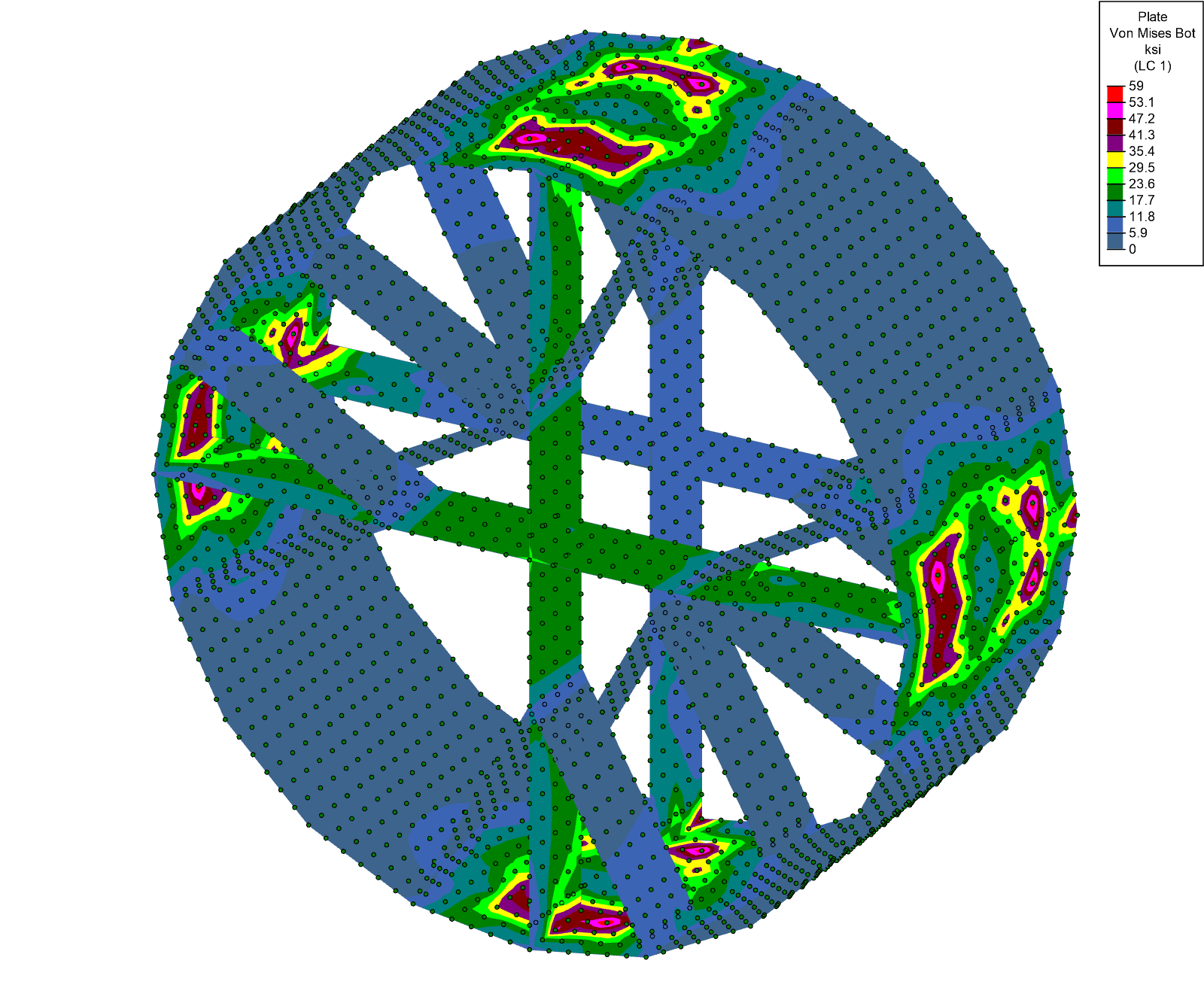

The more ornate elements of the structure including the atrium roof trusses, link rotunda, tree stair as well as various canopies were designed using RISA. For the trusses, AutoCAD geometry was imported into RISA-3D to perform a 2D analysis and obtain initial member sizes. These design elements were then included with the entire roof structure, including the columns in order to verify the full design. Additionally, the plate analysis features of RISA-3D were used in the design of the 40ft diameter link rotunda in order to determine stress concentrations at the locations were members were welded together. Overall, RISA-3D provided the engineer with a flexible solution that allowed for the modeling, analysis and design of complex structural elements.

Images 1-3: Architectural Photography & Design

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.