BRCC Patton Hall Addition

Flat Rock, NC

Project Quick Facts

Building Client

Blue Ridge Community College

Structural Engineer

Kloesel Engineering, P.A.

General Contractor

Vannoy Construction

Software Used

RISAFloor, RISA-3D, RISA-Revit link

Structural Components

Steel Framing, Masonry Shear Walls

Year Completed

Summer 2022 (Anticipated)

Project Background

The 78,739 sq-ft Patton Hall Addition (designed by architect Clark Nexsen) aims to be a welcome new development on the aging Blue Ridge Community College - Henderson County campus. Connecting to the existing Patton Building via an elevated walkway, this three-story addition will feature new industrial spaces, common areas, and modern science labs to better serve the students in the Flat Rock, NC Community. The steel and masonry structure features unique framing geometry and floor levels which mimic the Appalachian topography.

sq ft

story addition

span walkway

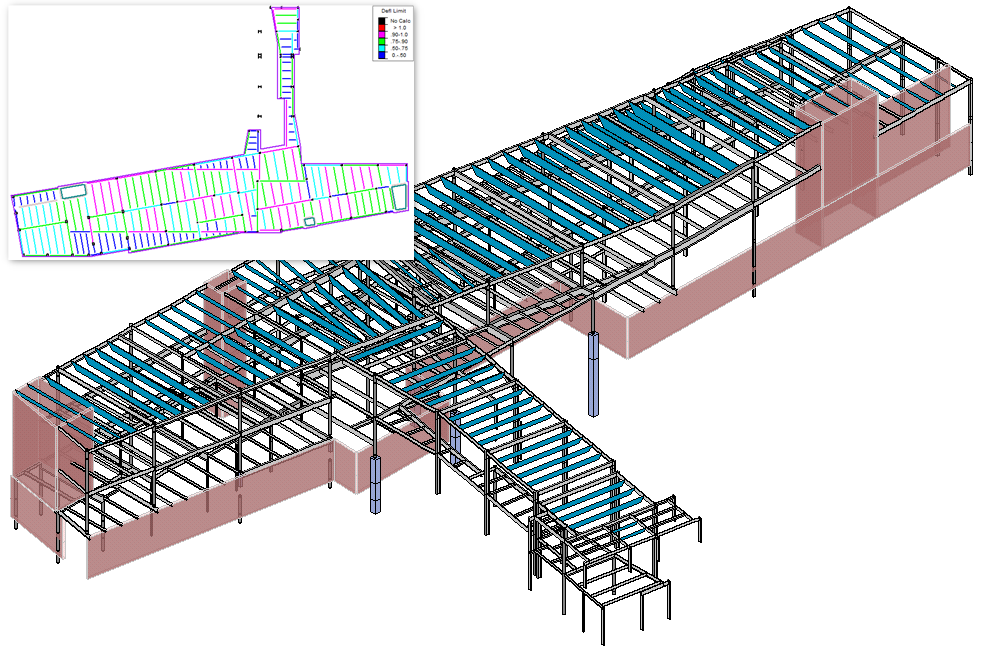

About the Structure

The architectural requirements of the building presented special challenges for the structural designers. Masonry shear walls and steel frames resist the lateral forces which include wind loading from rooftop screen walls. The floor system consists of composite and non-composite decking on hot rolled steel beams. The building’s skewed steel framing resulted in continuously varying span and loading conditions, creating few “typical” beam designs. Tying into an existing structure also required specialized framing layouts. The large amount of transfer beams also presented challenges when analyzing demand loads and deflections. Given the complex nature of the structure, the design would have been prohibitively time-consuming to check by hand.

"We were able to efficiently size composite beams and joists supported both on walls and steel columns, within the same model, which was very useful and time-saving."

Robyn Manhard, E.I.

How Were RISA Products Utilized?

Kloesel modeled the entire addition structure in one RISAFloor model to best capture the interaction between structural elements. Composite steel beams and roof joists were sized automatically for the demand loading based on design rules set up by the engineer that could be governed by strength, deflection, or even maximum beam depth. Architectural updates required frequent shifting of project grids, but these framing changes were made effortlessly within the RISAFloor graphical user interface and spreadsheets. RISA-3D was also used to analyze and design the steel braced and moment frames, as well as the masonry shear walls. The structural design was transferred to Revit using the RISA-Revit link, which allowed for construction drawings to be produced quickly and accurately. Stud counts, beam sizes, and end reactions were all imported to Revit and easily updated as needed during the design process. The RISA products used in this project allowed for an efficient and accurate design from start to finish.

Image 1: Clark Nexsen | Image 2-4: Kloesel Engineering, P.A.

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.