Liberty University Freedom Tower

Lynchburg, VA

Project Quick Facts

Building Client

Liberty University

Structural Engineer

Fox and Associates Consulting Engineers

General Contractor

Construction Management Associates, Inc.

Software Used

RISA-3D

Structural Components

Concrete Frame, Concrete Walls, Steel Frame

Year Completed

2018

Project Background

The 275-foot tall Freedom Tower serves as a centerpiece of Liberty University’s $1 billion campus rebuild. The 17-story tower and base building, which is home to the Rawlings School of Divinity, features classrooms, office space, conference rooms and an observation deck with spectacular views of the Lynchburg, VA campus. From the lobby, visitors can take one of two elevators up to the top of the tower or can choose to climb the 409 stairs to the top. Additionally, visitors can access rooftop terraces on the 2nd and 3rd floors as well as a large wrap-around plaza and garden pergola on the 4th floor.

tower

stories

office base

About the Structure

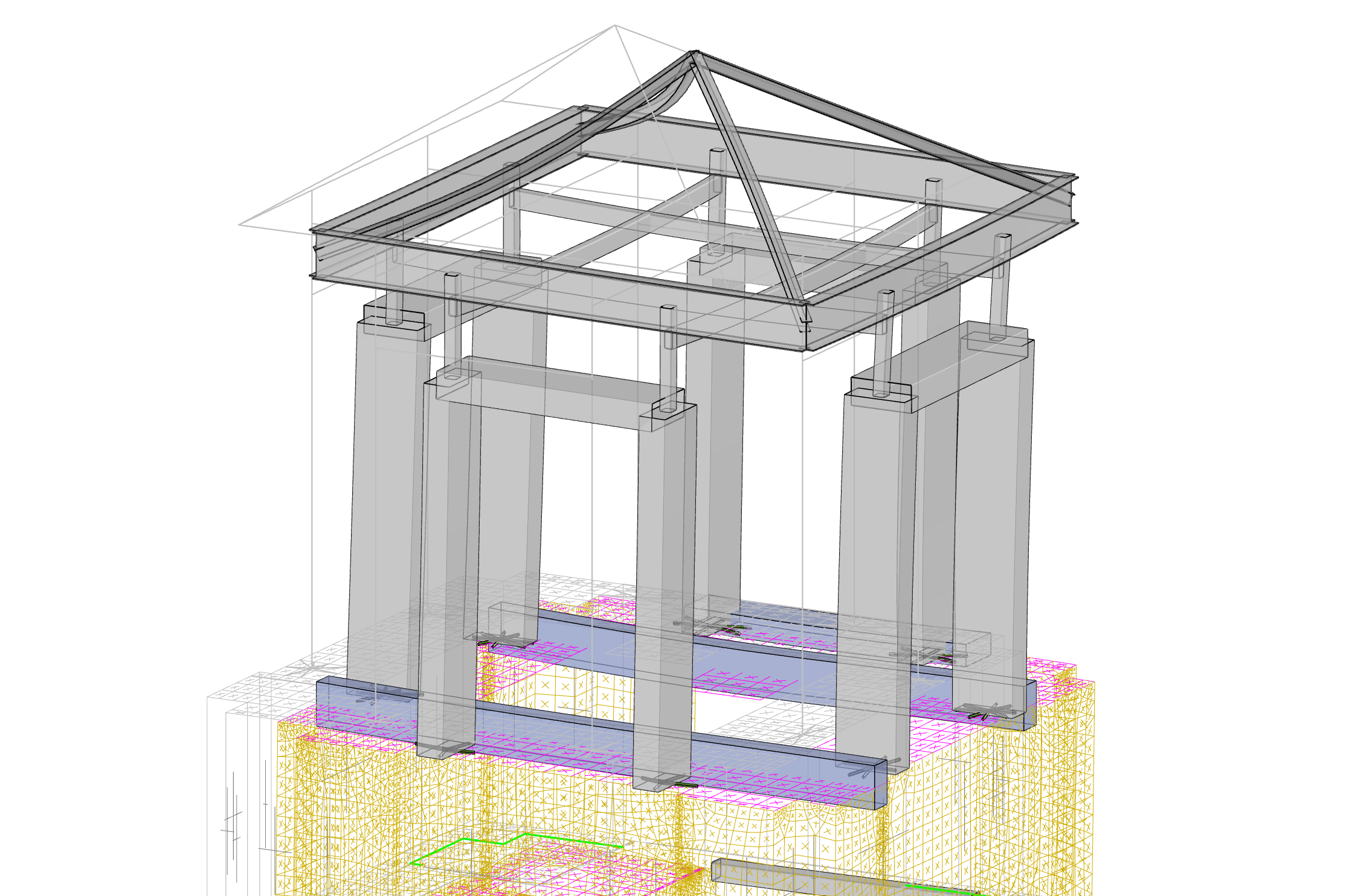

The tower served as one of the most significant project in the history of Fox and Associates due to its size and scope. The architectural design of the tower included glazing, wrapped around each corner of the 35’ x 35’ tower. This dramatically reduced the stability of the structure and resulted in nearly 150 vertical feet of unsupported edge at two corners of the elevator shafts. To remedy this situation and provide additional bracing at each floor, HSS tubes were installed in order to “link” the concrete shear walls to each other on each level. Additionally, the rooftop “crown” consists of a steel structure which supports a carillon of 25 bells.

"The entire project was a challenge and we couldn’t have done this project without RISA-3D."

Clive Fox, PE

How Were RISA Products Utilized?

RISA-3D was used extensively to model and design the entire concrete shell of the structure as well as all of the steel framing at both the individual floors and at the roof (which supports a carillon of 25 bells). RISASection was also utilized to model the large, custom 25' tall hollow steel columns that support the crown. Additionally, the tower was analyzed as a flexible structure, with wind loads generated automatically in RISA-3D and then increased in order to simulate the additional load as a result of the flexibility. These “simulated” wind loads were then compared to loading derived from a special wind loading software in order to confirm the load being used in analysis and design. Overall, RISA-3D provided the engineer with a flexible solution that allowed for the proper modeling, analysis and design of all aspects of this challenging project.

Image 1: Liberty University | Images 2-3: Fox & Associates

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.