Frozen Fortress at GLOW Nashville

Nashville, TN

Project Quick Facts

Software Used

RISA-3D, RISAConnection

Structural Components

Steel Framing

Year Completed

2019

Project Background

GLOW Nashville is the ultimate holiday display located at First Tennessee Park in Nashville, TN. The experience for attendees includes one of the tallest Christmas trees in the country (at over 100ft), more than 4 million holiday lights, a 170 ft long tube park built over the stadium seats, a life-size Santa’s workshop and a Frozen Fortress Ice Skating Rink with a 3-story viewing platform. The event opens just after Thanksgiving each year and runs through New Years Eve.

tree

tube park

story platform

About the Structure

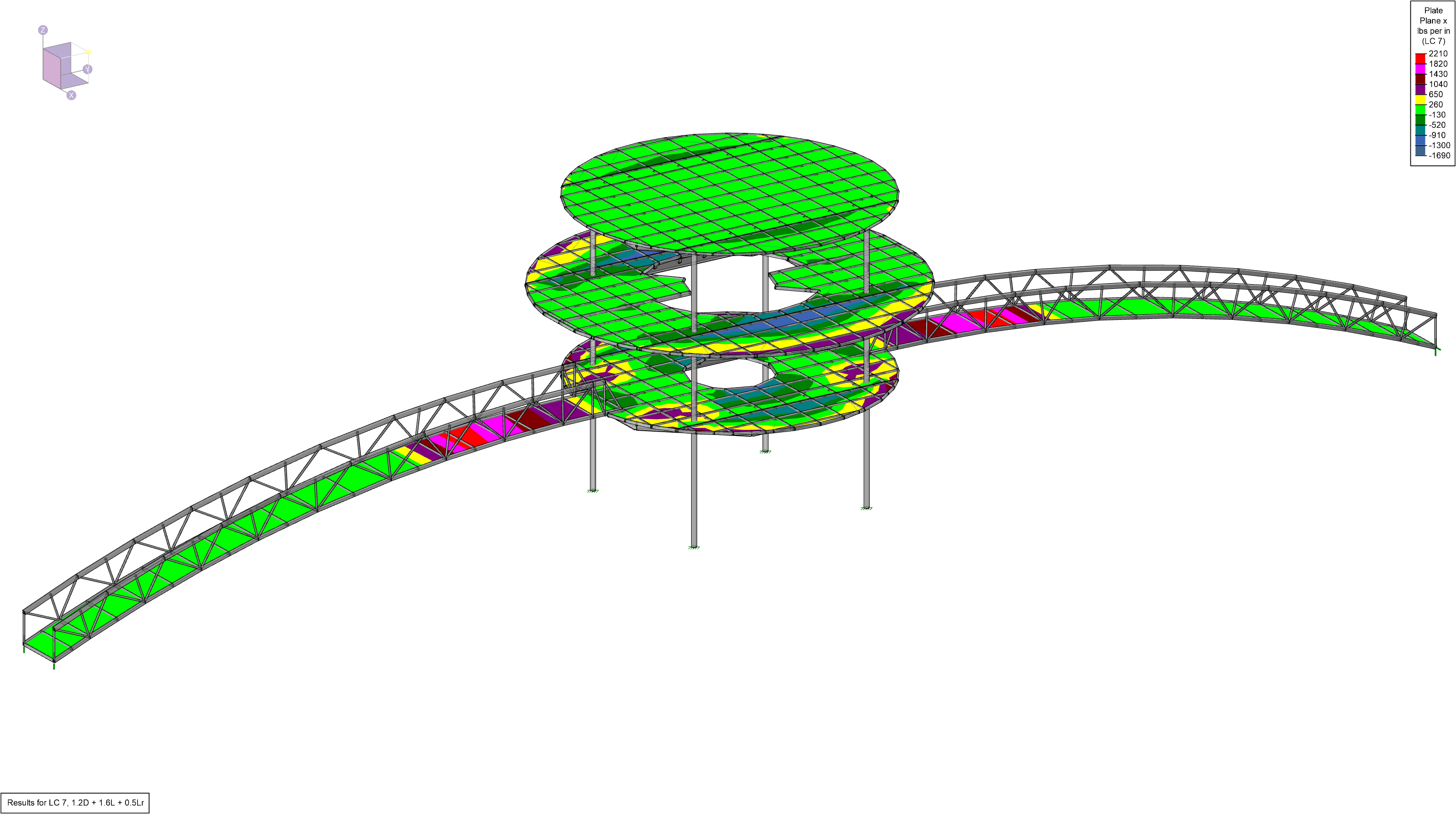

The focal point of the display is the 3-story viewing platform, known as the Frozen Fortress, which sits as the center of the ice skating rink. The 30 ft tall, temporary structure includes a spiral staircase in the middle as well as two 70 ft long by 6 ft wide pedestrian bridges that span over the ice skating rink allowing visitors access to the structure’s viewing platforms. The main structure includes a modular, hot rolled steel system (HSS tubes and wide flanges) that is designed to be easily erected and then taken apart, shipped, stored and ready for the next use. Additionally, the temporary nature of the structure, as well as its location (on a baseball field) mean that there are no foundations, this means that all forces need to be resolved within the structure itself. Even though there were no foundations, the base of each column was analyzed as fixed due to the fact that they would be encapsulated in ice during the structures use.

"For us, RISA-3D was the right program to use because of its ability to handle complex geometry while also being able to report loading information in a way that allows for easy review and verification."

Jordan Tlumak, PE

How Were RISA Products Utilized?

Engineers at Epiq Structural Solutions utilized RISA-3D to model and analyze the entire structure with specific attention paid to the pedestrian bridge and “waffle” floor system. The analysis of the pedestrian bridges were unique due to the fact that the loaded condition would cause the bridge to slide since it was not anchored to the ground. As a result, additional lateral loads were introduced into the model to account for the sliding. When designing the “waffle” floor system, rigid links were used in order to achieve proper connection and load distribution of members spanning over top of each other. Additionally, due to the floor systems modularity, RISA-3D was used to evaluate loads and determine the connections that would be required between each module. Finally, RISAConnection was employed to design standard gravity connections as well as simplified versions of the complex lateral moment connections.

Image 1: GlowCo | Image 3: Jordan Tlumak | Image 4: Jessica DiMento

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.