McDonald's Net-Zero Quick Service Restaurant

Kissimmee, FL

Project Quick Facts

Building Client

McDonald's Corporation

Structural Engineer

CPH, Inc.

General Contractor

Southland Construction, Inc.

Software Used

RISA-3D, RISAConnection

Structural Components

Structural Steel, Braced Frames, Steel Connections

Year Completed

2020

Project Background

McDonald’s first global net-zero quick serve restaurant located in Kissimmee, FL aims to provide the fast food giant with a venue that will serve as a learning hub to test and develop sustainable solutions. The 8,000 sq-ft renovation/remodel incorporates solar panels, living walls, natural shading, solar lighting, innovative heat reduction techniques and unique structural steel framing to achieve sustainable design that will together create enough renewable energy on-site to cover the buildings energy needs on a net annual basis. To solidify the restaurant’s Net Zero Energy status, McDonald’s will also pursue the International Living Future Institute’s Zero Energy Certification. The restaurant also includes a spacious outdoor dining patio as well as storytelling kiosks and environmental-themed graphics, enlightening guests as to how the high-performance building’s renewable energy and efficiency features work and why they’re important.

sq ft

stories

energy offset

About the Structure

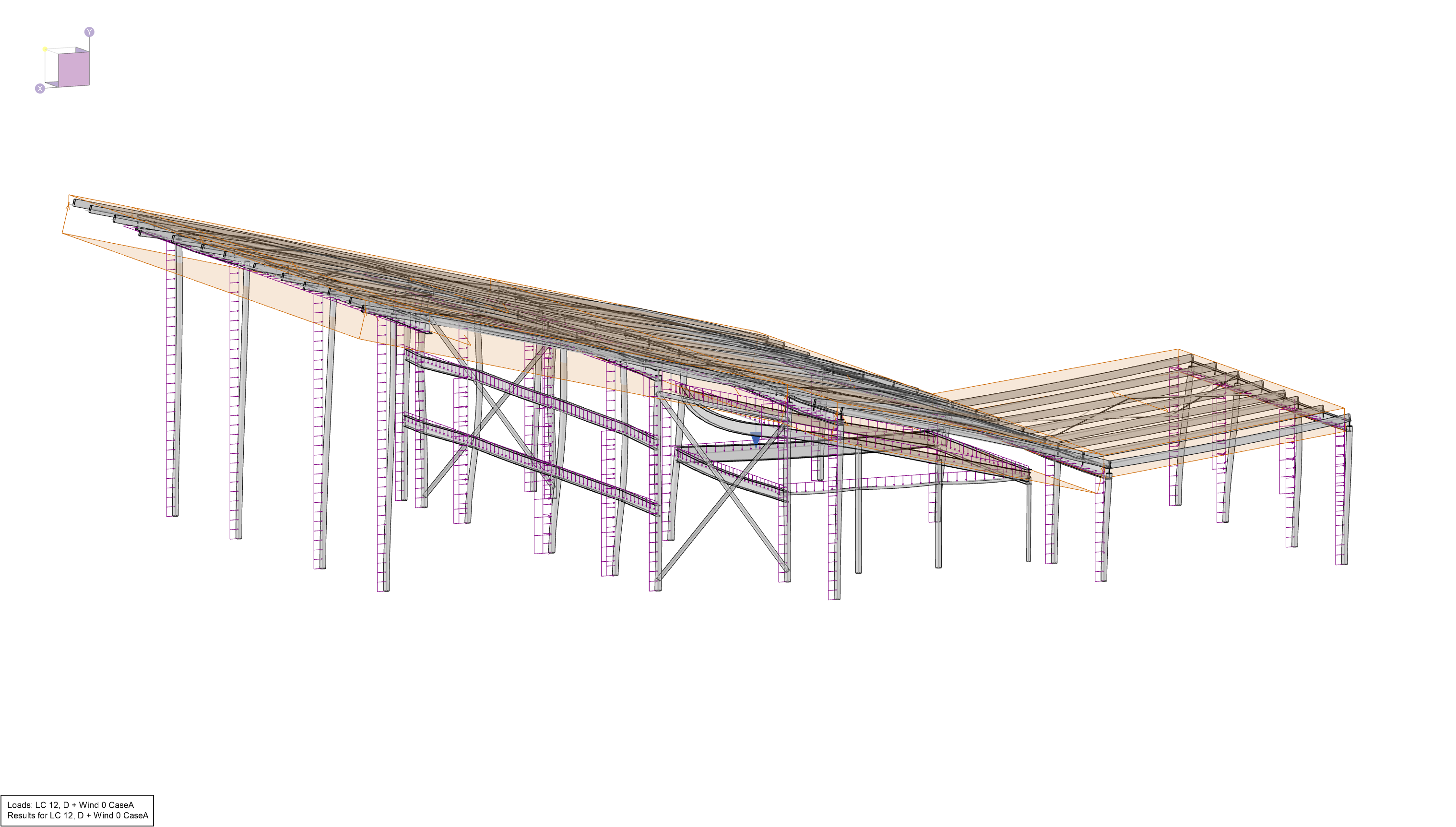

The project’s location near Walt Disney World demanded a landmark type structure that would hold its own among the countless theme park attractions nearby. To achieve this, structural steel was used to provide endless design possibilities for the architect and engineer, with the featured design element being an 18,000 sq-ft butterfly roof that includes a 35ft cantilever and support for over 1,000 solar panels. The roof's shape also created incredibly high wind loads (as well as uplift forces) and as a result, deep caisson foundations were utilized to help anchor the structure. Finally, the main CHS columns at the drive-thru (that support the tallest end of the roof) were filled with concrete to two-thirds of their height in order to control column slenderness.

"RISA-3D's output (both graphical and tabular) allow us to easily understand and solve any structural framing issues with ease."

José Miguel Ortiz, PE

How Were RISA Products Utilized?

Due to the challenging structural layout and loading conditions of the building, engineers at CHP utilized RISA-3D to create a 3D model of the entire steel structure. One such condition was the heavy loads (due to both wind uplift and the weight of the solar panels) at the roof cantilever. The ability to precisely model the roof framing as well as the loading allowed engineers to visualize the deflected shape to ensure that the required maximum deflection (roughly 1”) was achieved. Additionally, RISA-3D’s robust detailed reports allowed the design team to easily identify where members were failing and how they needed to be optimized, ultimately saving time and structural weight. Finally, RISAConnection (along with other in-house tools) were used by the engineer to design the shear and moment connections for the CHS columns and the rest of the project. Overall, RISA-3D played an important role in achieving the structural, sustainable and aesthetic goals of the project.

Photos Courtesy of Southland Construction, Inc.

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.