Phillips 66 Freeport LPG Export Terminal

Freeport, TX

Project Quick Facts

Building Client

Phillips 66

Structural Engineer

Burns & McDonnell

General Contractor

Zachry Construction

Software Used

RISA-3D, RISA-Tekla Link

Structural Components

Steel Frame, Steel Truss

Year Completed

2016

Project Background

The Phillips 66 Freeport LPG Export Terminal, located on the Gulf of Mexico in Freeport, TX is a 100-acre facility used for the export of over 4 million barrels liquefied petroleum gas per year. Due to the facility’s location on the water, the finished modules were shipped in on barges and could therefore be larger than what trucks could typically accommodate.

acres

barrels LPG/year

module width

About the Structure

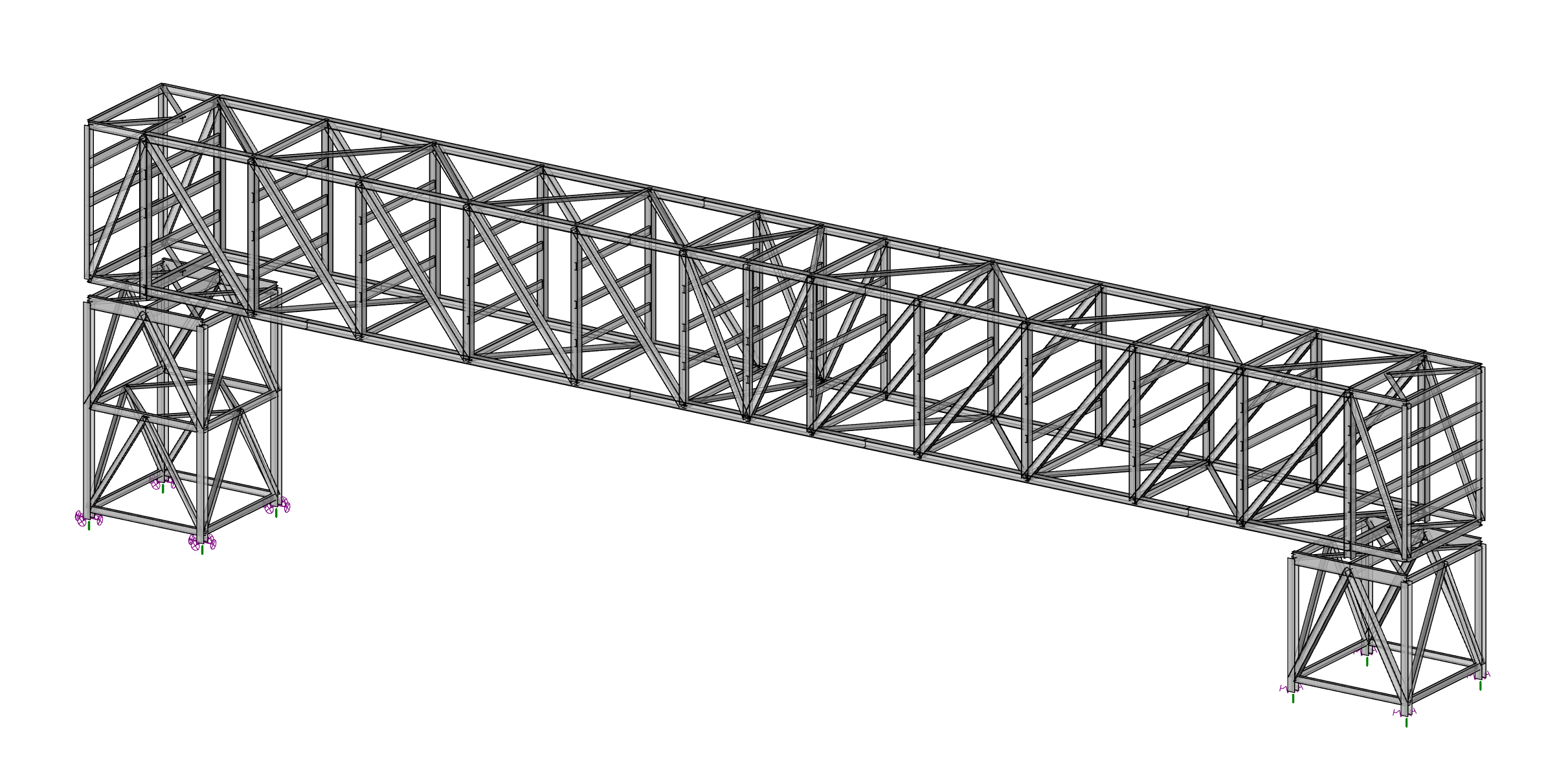

Because of the compressed nature of the project schedule, the steel pipe rack structures were designed as modular units that could be built offsite, with the largest unit measuring 40 ft tall, 32 ft wide and 110 ft long, while weighing in at 170 tons. These units were transported to the site on barges and erected using multiple cranes. In addition to the pipe racks, three 200 ft pipe bridges were needed to span the existing levee. In total, 6150 tons of steel were used and the schedule of the project was significantly reduced as a result of the modular construction techniques that were utilized.

"We’re trying to figure out how to interface with our fabricators and having a design program that can interface directly with Tekla, saves us a lot of time and saves us from having to manually input beam and column sizes."

Joshua Brown, PE

How Were RISA Products Utilized?

Each modular unit was analyzed and designed using RISA-3D for gravity, hurricane force wind loading and also “motion” loading conditions that would arise during transport at sea. In addition to the steel pipe rack modules, the pipe bridges were also designed in RISA-3D and utilized a modular system which allowed the units to arrive on-site fully assembled including all required pipe rack. Finally, the rack and pipe bridge modules were sent back and forth between the engineer and fabricator using the bi-directional RISA-Tekla link. This workflow proved to be a time saver and allowed for a more in-depth coordination between all parties involved.

Images 1-3: Phillips 66

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.