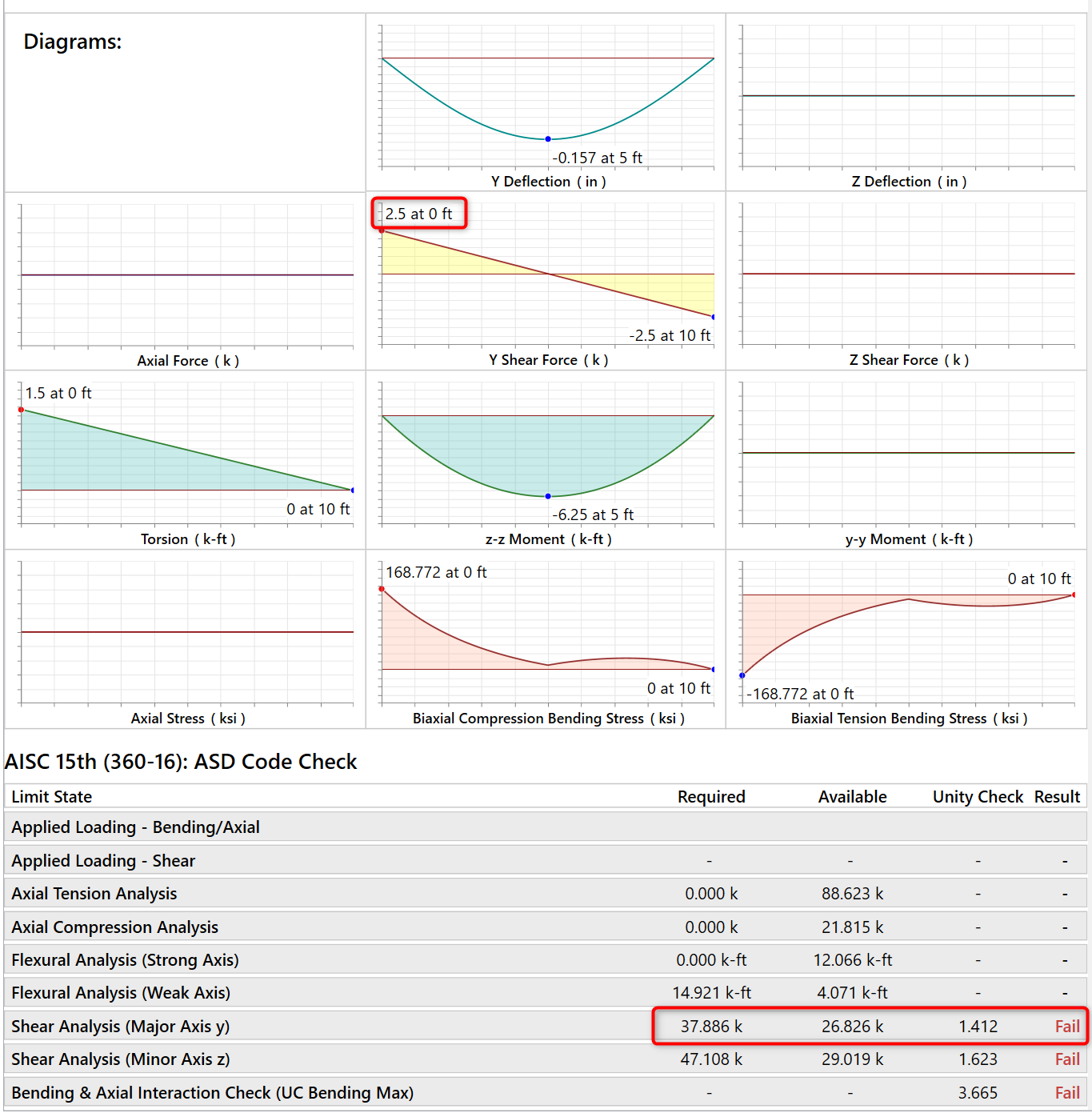

When solving a RISA-3D model you may find you have a Shear UC (unity check) much higher than expected from bending shear alone. If you open the detail report and compare the shear demand to the shear capacity you may see that the demand/capacity is less than the Max Shear Check reported.

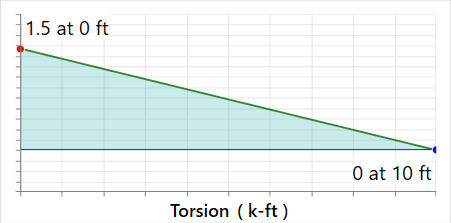

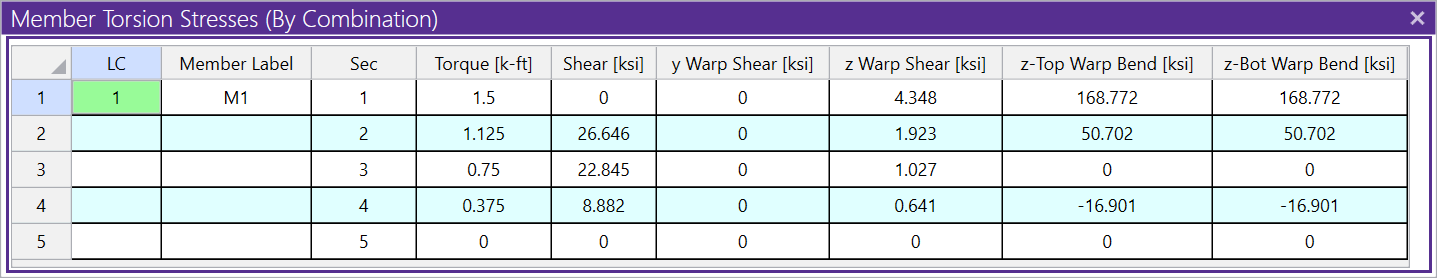

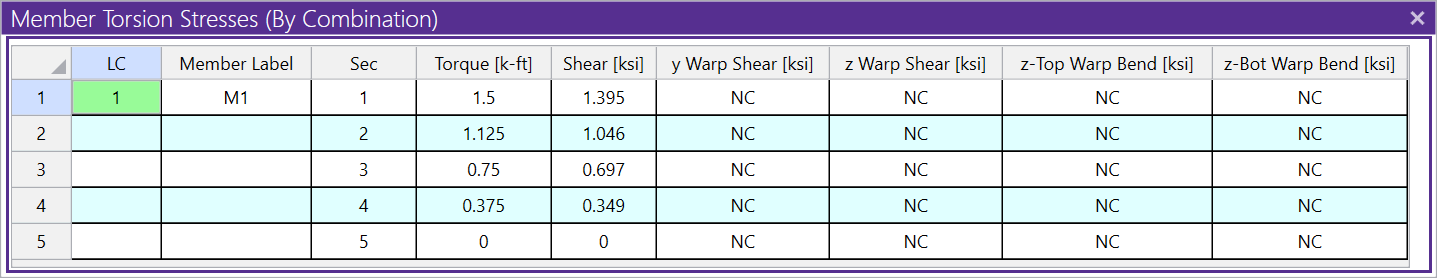

What is likely occurring is that the member has torsion in it. In RISA-3D both the bending and shear demands are affected by torsion, though it is shear that usually causes the most problems. If you look at the detail report and in the Member Torsion spreadsheet results you can see this torsion.

Warping Member (Wide Flange, Channel, etc):

Non-Warping Member (Tube, Pipe, etc):

Generally speaking wide flanges and channels work very poorly in torsion, while tube sections are much more efficient. Eliminating torsion or using a more efficient section are common ways to eliminate this problem. Note that this torsion problem can happen for all material types.