Connecticut Children's Medical Center Tower Addition

Hartford, CT

Project Quick Facts

Building Client

Connecticut Children’s Foundation

Structural Engineer

CannonDesign

General Contractor

DPR

Software Used

RISA-3D

Structural Components

Steel Trusses, Cantilevered Canopy, Screen Wall, Moment Frames

Year Completed

2025

Project Background

Connecticut Children’s Medical Center in Hartford, originally built in the early 1990s, was designed with a steel podium capable of supporting future vertical expansion. Three decades later, CannonDesign was tasked with realizing that expansion in a way that responded to contemporary healthcare delivery needs. Instead of the semicircular tower envisioned in the original scheme, the design team reconfigured the addition as a rectilinear, eight-story, 190,000-sq.-ft clinical tower rising above the existing podium and supported in part by new basement-level foundations. The reimagined tower integrates seamlessly with the existing structure while introducing programmatic flexibility for the future. Most notably, the expansion required a series of secondary yet highly visible structural elements—including a pedestrian bridge, entry canopy, and rooftop framing—that together embodied both the symbolic and functional goals of the project.

sq ft

pedestrian bridge

clear span

About the Structure

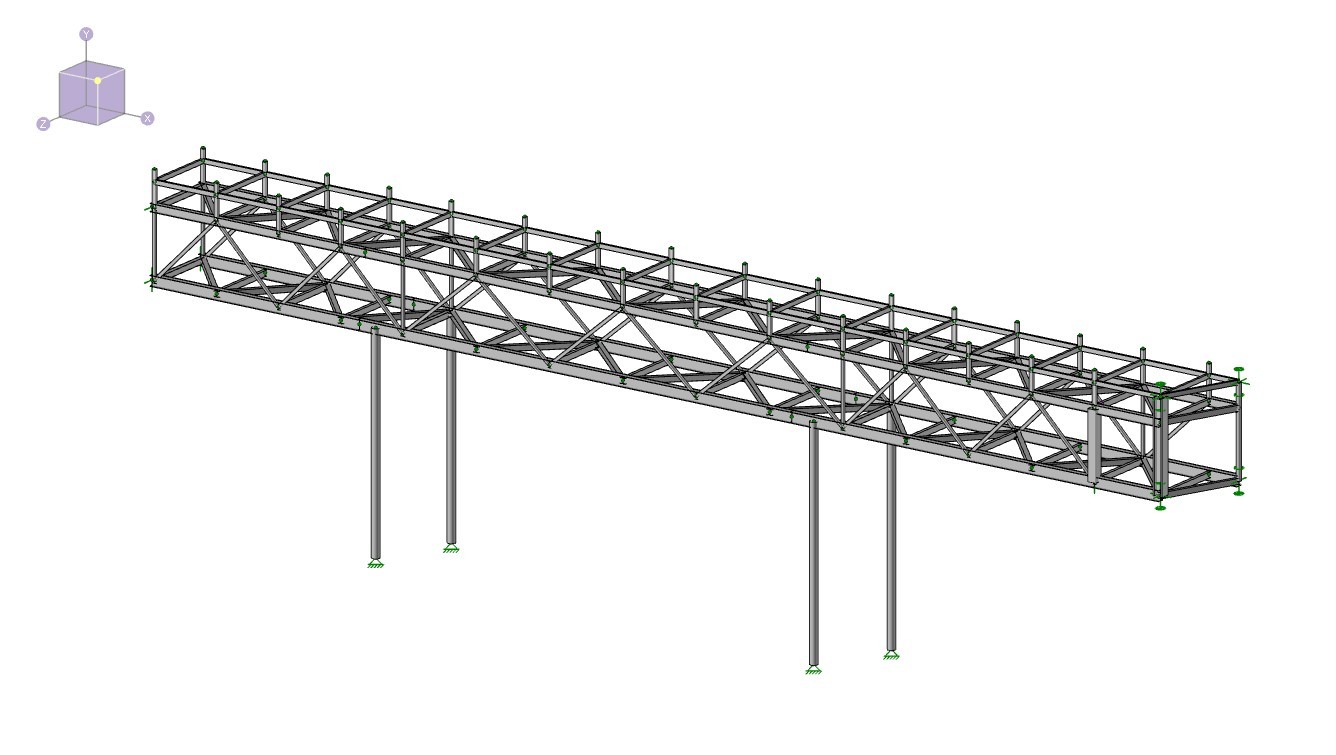

The defining feature of the addition is the 150-ft-long pedestrian bridge that spans Washington Street, connecting the new clinical tower with a parking structure across a four-lane roadway. This signature element was designed as a series of story-high box trusses, with the longest clear span reaching 70 ft. The top chord, exposed to public view, consists of W14×74 members, while the bottom chord below the floor level uses W18×86 sections. Six-inch-diameter HSS diagonal web elements were directly welded to the chords, and all exposed surfaces were detailed to AESS Level 3 standards. Two pairs of HSS14 columns provide gravity support, while lateral loads are transferred into the tower and garage through the truss chords. Continuous diaphragm bracing using W10×39 members was incorporated at both floor and roof levels to provide additional stiffness. The bridge was prefabricated offsite in three spans, shipped to the hospital, and erected sequentially to minimize disruption. This approach demanded an adaptable design, as column placements were revised during construction to avoid existing underground utilities.

"We were able to be very customized in RISA-3D—building models that mimicked our Revit geometry and quickly seeing how design changes impacted behavior. That level of control was essential."

Bassem Almuti, PE

How Were RISA Products Utilized?

CannonDesign engineers relied on RISA-3D to address the complex behavior of the suite of auxiliary structures that accompanied the tower expansion. For the bridge, RISA-3D models were essential in exploring multiple column configurations after unforeseen site conditions required real-time design changes. The software allowed the team to evaluate the structural efficiency of alternatives such as single columns with Y-shaped branches versus paired columns, providing DPR Construction and Shepard Steel with clear, data-driven options that could be implemented without delaying construction. RISA-3D also supported the staged erection analysis of the prefabricated bridge. By modeling temporary conditions—such as only the first span being set in place before the others could be erected—the design team was able to develop a temporary bracing system that maintained stability while allowing architectural cladding and mechanical systems to be installed ahead of schedule. Beyond the bridge, several auxiliary structures required highly customized design. Starting with simplified 2D models and extending into 3D configurations, RISA-3D provided quick insight into column sizing, moment demands at the base, and the interaction of wind, snow, and roof live loads for the cantilevered entrance canopy. Similarly, the rooftop screen wall system and mechanical dunnage platforms were modeled in RISA-3D to account for wind tunnel–derived pressures and late-stage mechanical equipment selections.

Images 1, 2, 3, & 4: Bassem Almuti

Reach an Engineer

Connect with the Experts.

We have the engineering staff ready to assist you.